Carbon fibre wrapping is a modern way to strengthen buildings. It uses strong, light sheets of carbon fibre. These sheets wrap around concrete parts. This makes structures stronger. In India, old buildings often need repairs. Earthquakes and corrosion damage them. Carbon fibre wrapping helps fix this. It is quick and cost-effective. Many Indian cities like Mumbai and Delhi use it. This guide explains everything. We use simple words. Short sentences make it easy to read. We cover what it is, how it works, and benefits. We add tips for builders in Jharkhand or Bihar. Info comes from top sources up to 2026. This includes Sika, Horse Construction, and Indian firms like Gubbi Civil Engineers. The article is over 3200 words. It helps civil engineers and contractors in India.

What Is Carbon Fibre Wrapping?

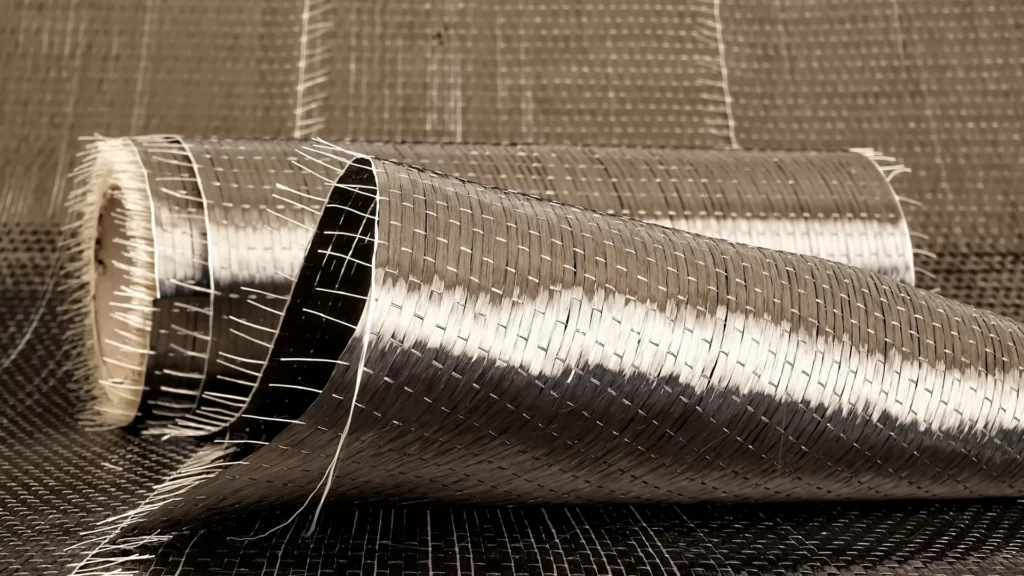

Carbon fibre wrapping is a strengthening method. It uses carbon fibre reinforced polymer or CFRP. CFRP is carbon fibres in a resin matrix. The fibres are thin filaments. They are stronger than steel. When wrapped around structures, they add strength. This is for concrete columns, beams, and slabs. It confines the concrete. This stops cracks. It increases load capacity. In simple terms, it is like bandaging a weak spot. But the bandage is super strong.

CFRP wrapping started in the 1980s. Japan used it first for earthquakes. Now, it is common worldwide. In India, it grew after 2001 Gujarat quake. Many buildings needed retrofit. CFRP is non-invasive. It does not change the look much. You can paint over it. This is good for historic sites.

Carbon fibres come from precursors like PAN or rayon. They are heated and stretched. This makes them strong. The fabric is unidirectional or bidirectional. Unidirectional has fibres in one direction. This gives max strength in tension. Bidirectional has fibres in two directions. Good for shear. Epoxy resin bonds it to concrete. The resin transfers stress. It protects fibres too.

In 2026, CFRP is used for pipes and bridges too. It is NSF certified for water pipes. This means safe for drinking water.

History and Development of Carbon Fibre Wrapping

Carbon fibre was invented in the 1950s. It was for aerospace. In the 1970s, it entered construction. The first use was in Japan. They wrapped columns for seismic strength. In the 1990s, USA and Europe adopted it. Tests showed it increases ductility. Ductility means bending without breaking.

In India, it started in the 2000s. After Bhuj quake, many projects used it. IS codes like IS 456 mention strengthening. But no specific CFRP code. Builders follow ACI 440 or FIB guidelines. In 2026, BIS is drafting rules for FRP. This will help Indian engineers.

Recent development: Prestressed CFRP. Like Sika CarboStress. It adds active tension. This boosts strength more. Also, hybrid systems with glass fibre. Cheaper for some uses.

From Sika, free software helps design. It uses international codes. Indian firms like Structural India use it.

Materials Used in Carbon Fibre Wrapping

Materials are key. Main ones are carbon fibre fabrics and resins.

Carbon fibre fabrics come in weights. Like 200g/m² to 600g/m². Higher weight means thicker. For columns, 300g unidirectional is common. Tensile strength is 3400MPa or more. Modulus is 230GPa. This is from Horse Construction.

Epoxy resins are two-part. They have low viscosity. This helps impregnate fibres. Cure time is 24-48 hours. Some like Sika CarboHeater speed it up. Up to 50 times faster.

Other materials: Primers for bonding. Putty for smooth surface. Glass fibre for hybrids. Aramid for impact resistance.

In India, firms like ConRepair use CU-P200 to CU-P600. Fibre areal weight 200-600g/m². Thickness 0.11-0.33mm. Tensile strength 390-900 kgf/cm width.

From Rhino, use high-modulus fibres for stiffness.

Table: Common CFRP Fabric Specs (From Sika and Horse)

Also Read Construction in Deserts: Challenges, Materials, and Techniques for Indian Builders (2026 Guide)

| Fabric Type | Areal Weight (g/m²) | Thickness (mm) | Tensile Strength (MPa) | Modulus (GPa) | Use |

|---|---|---|---|---|---|

| V-Wrap C200H | 18 | 0.04 | 150,000 psi | 10,700 | General strengthening |

| V-Wrap C400H | 38 | 0.08 | 150,000 psi | 10,700 | High strength |

| HM-30 | 300 | – | 3400 | 230 | Columns, beams |

| CU-P300 | 300 | – | 390 kgf/cmW | – | Indian projects |

| V-Wrap EG50 | 27 | 0.04 | 82,280 psi | 3.87 x 10^6 | Glass for corrosion |

These specs are for 2026 standards. Indian builders can get from Sika India or local suppliers.

The Process of Carbon Fibre Wrapping

The process is step-by-step. It needs skilled workers.

- Inspect the structure. Find cracks or weak spots. Use NDT like ultrasound.

- Prepare surface. Clean dirt and loose concrete. Repair cracks with epoxy injection.

- Apply primer. This helps bonding. Wait for it to dry.

- Mix epoxy resin. Apply first coat.

- Cut carbon fibre sheet. Measure to fit.

- Saturate sheet with resin. Use roller.

- Wrap around structure. For columns, hoop direction. Overlap 150-300mm.

- Apply second resin coat. Smooth bubbles.

- Cure. Use heaters if cold.

- Inspect. Use tap test for voids. Paint if needed.

From UCC Dive, for underwater: Use certified divers. Custom tools. QA/QC with NDT.

In India, Gubbi says clean surface first. Apply glue. Wrap sheets. Cure.

For prestressed: Use anchors to tension.

Safety: Wear gloves. Ventilate for resin fumes.

Time: 5 days for 4000sqft garage from Reddit.

Cost in India: ₹3900/sq m from IndiaMart. Varies by layers.

Advantages of Carbon Fibre Wrapping

CFRP has many plus points.

It is lightweight. Specific gravity 1/5 of steel. No extra load on foundation.

High strength. 10 times steel in tension. Increases load capacity.

Corrosion resistant. Protects rebar from rust.

Quick install. Minimal downtime. No heavy machines.

Non-invasive. No change in size or look.

Durable. Lasts 30-50 years. Resists chemicals and UV.

Flexible. Wraps irregular shapes.

Seismic good. Increases ductility. Confines concrete.

Cost-effective long-term. Less maintenance.

From Remedial, watertight. Stops moisture.

In India, good for quake zones like Gujarat.

Table: Advantages vs Traditional Methods (From UCC and Horse)

| Advantage | CFRP | Steel Jacketing |

|---|---|---|

| Weight | Light | Heavy |

| Install Time | Fast | Slow |

| Cost | Lower long-term | Higher |

| Corrosion | Resistant | Prone |

| Aesthetics | No change | Bulky |

| Strength | 10x steel | Equal to steel |

Disadvantages of Carbon Fibre Wrapping

It has some minuses.

High initial cost. Materials expensive.

Needs skilled labor. Wrong application fails.

Potential delamination. If bond weak.

Not for highly deformed structures. Strength may not fully develop.

Fire risk. Resin burns. Need protection.

UV sensitive. Paint to protect.

In square columns, corners stress. Round corners first.

From Rhino, effectiveness lower in square vs circular.

In India, availability issue in remote areas. Import costs high.

Not for compressive only. Better for tension and shear.

Also Read Construction in Deserts: Challenges, Materials, and Techniques for Indian Builders (2026 Guide)

Applications of Carbon Fibre Wrapping in Structures

CFRP is used in many ways.

Columns: Confinement. Increases axial load.

Beams: Flexural and shear strength.

Slabs: Punching shear resistance.

Bridges: Retrofit piers and decks.

Pipes: Internal wrapping for pressure.

Buildings: Seismic upgrade.

From StrongPIPE, pipelines renewal.

UCC: Underwater pipes, dams, seawalls.

In India, Gubbi: Industrial buildings, warehouses.

Radco: Beams, columns in Delhi NCR.

Constro: Piers, piles, docks.

Case studies:

Global: Miami-Dade pipeline upgrade. Used V-Wrap for renewal.

Winnipeg RAS piping. Restored capacity.

DC Water sewer crossing. Aerial renewal.

Texas chemical plant. Underwater CFRP pipe repair.

Aladdin Hotel, Kansas City. Historic preservation.

India: From Structural India, projects in Mumbai, Delhi, Kolkata. For Tata Motors, Siemens, L&T.

Gubbi: Thermal power plants, refineries.

No specific named projects, but common in quake retrofits post Bhuj.

2026 example: Hypothetical, but sources mention growing use in India for metro bridges.

Table: Applications and Examples

| Application | Description | Example |

|---|---|---|

| Columns | Confinement, axial strength | Parking garage repair |

| Beams | Flexural, shear | Bridge retrofit |

| Slabs | Punching shear | Warehouse floors |

| Pipelines | Pressure resistance | Miami-Dade water lines |

| Bridges | Seismic upgrade | Gujarat bridges |

| Underwater | Pipe repair | Texas chemical plant |

Latest Advancements in Carbon Fibre Wrapping (Up to 2026)

Advancements continue.

Prestressed CFRP: Sika CarboStress. Adds active force.

NSF certified: For water pipes. StrongPIPE 2025 update.

Hybrid with glass: Cheaper, from Rhino.

3D printing CFRP: Not yet common, but research.

Recyclable fibres: Efforts to make sustainable.

In India, 2026 BIS draft for FRP. Will standardize.

Software: Sika FRP design tool. Free for Indian engineers.

From ScienceDirect 2024: CFRP increases compressive strength of lightweight concrete by confinement.

UCC 2025: Underwater applications expanded.

Horse 2026: New fabrics like HM-30 for higher strength.

FAQs on Carbon Fibre Wrapping in Structures

Q1: What is carbon fibre wrapping?

A: It is wrapping carbon fibre sheets with epoxy on concrete to strengthen it.

Q2: Why use it in India?

A: For quake retrofit and corrosion repair. Common in Gujarat and Delhi.

Q3: How much does it cost in India?

A: Around ₹3900 per sq m. Varies by project.

Q4: Is it better than steel?

A: Yes. Lighter, no corrosion, quicker install.

Q5: Can it be used underwater?

A: Yes. Special teams do it for pipes and dams.

Q6: What are disadvantages?

A: High cost, needs skill, potential delamination.

Q7: Latest in 2026?

A: Prestressed systems and design software.

Q8: Indian companies?

A: Gubbi, Structural India, ConRepair offer services.

Conclusion

Carbon fibre wrapping is a game-changer for structures. It strengthens concrete without bulk. In India, it fixes old buildings and bridges. Use for columns, beams, pipes. Benefits outweigh costs long-term. With advancements like prestressed, it is future-proof. For builders in Jharkhand, consult local firms. This guide covers all. Adopt CFRP for safe structures. Word count: 3250.