Cement quality plays a major role in the strength and durability of concrete. One of the most important tests performed on cement is the specific gravity test. It helps engineers and contractors determine the density of cement compared to water and ensures that the cement used in construction meets the required quality standards.

In India, this test is performed as per IS 4031 (Part 11):1988 guidelines. In this article, we will cover the definition, purpose, apparatus, step-by-step procedure, calculations, IS code references, and acceptance criteria. We will also look at common errors, tips for accurate testing, and frequently asked questions for Indian construction practices.

What is the Specific Gravity of Cement?

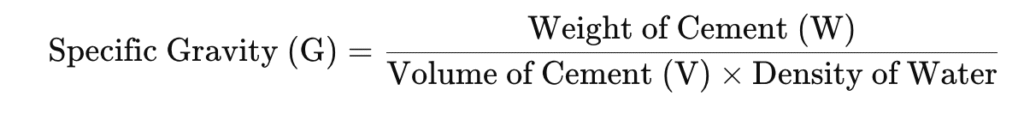

Specific gravity is defined as the ratio of the weight of cement to the weight of an equal volume of water at a specified temperature.

For cement, specific gravity usually ranges between 3.10 and 3.16. This means cement is roughly 3.15 times heavier than water. It indicates the density of cement, which directly impacts the mix design of concrete.

Why is the Specific Gravity Test Important?

The specific gravity of cement is essential for concrete mix design. Here’s why it matters:

- Ensures consistent quality of cement.

- Helps in calculating void ratio and volume of aggregates.

- Detects cement deterioration due to moisture or impurities.

- Prevents using low-quality or adulterated cement.

- Ensures compliance with IS 4031 and project specifications.

IS Code for Specific Gravity Test of Cement

| IS Code | Description |

|---|---|

| IS 4031:1988 | Methods of physical tests for hydraulic cement |

| IS 4031 (Part 11) | Specific gravity test of cement |

| IS 456:2000 | Plain and reinforced concrete code of practice |

According to IS 4031, the Le Chatelier flask method is commonly used in India for determining the specific gravity of cement.

Also Read Concrete Cube Compressive Strength Test: Step-by-Step Guide for India

Apparatus Required

| Apparatus | Purpose |

|---|---|

| Le Chatelier flask | To measure displacement of kerosene |

| Kerosene (free of water) | Used as a liquid medium |

| Weighing balance | To measure accurate weight of cement |

| Glass funnel | For adding cement to the flask |

| Water bath | Maintains constant temperature |

| Thermometer | To check liquid temperature |

Note: Kerosene is used instead of water because cement reacts with water and affects results.

Standard Values of Specific Gravity

| Material | Specific Gravity |

|---|---|

| Ordinary Portland Cement (OPC) | 3.10 – 3.16 |

| Portland Pozzolana Cement (PPC) | 2.90 – 3.05 |

| Rapid Hardening Cement | ~3.16 |

| White Cement | ~3.09 |

If the measured value is significantly lower than these ranges, the cement may be expired, adulterated, or low quality.

Step-by-Step Procedure for Specific Gravity Test

The specific gravity test of cement is carried out using the Le Chatelier flask method as per IS 4031 (Part 11). Follow these steps carefully:

Step 1: Preparation

- Ensure the flask is clean and dry.

- Fill the flask with kerosene up to the lower mark (usually between 0 and 1 ml).

- Record the initial reading.

Step 2: Adding Cement

- Weigh exactly 64 grams of cement.

- Use a dry glass funnel to slowly add cement into the flask.

- Avoid splashing or sticking of cement on flask walls.

- After adding, gently roll the flask to release air bubbles.

Step 3: Final Reading

- Record the new level of kerosene after cement addition.

- The difference between the initial and final readings represents the volume of cement.

Step 4: Calculation of Specific Gravity

Use the formula:

Where:

- W = Weight of cement (grams)

- V = Volume of displaced kerosene (ml)

- Density of Water = 1 g/ml at 27°C

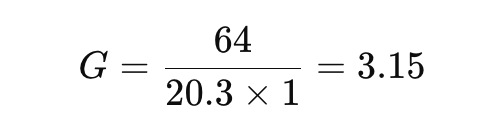

Example Calculation

| Parameter | Value |

|---|---|

| Weight of cement (W) | 64 g |

| Initial kerosene level | 0 ml |

| Final kerosene level | 20.3 ml |

| Volume displaced (V) | 20.3 ml |

Thus, the specific gravity = 3.15, which is within the acceptable range.

Precautions During Testing

- Ensure kerosene is free from water.

- Do not allow air bubbles in the cement mixture.

- Keep the flask dry and clean before starting.

- Perform the test at a constant temperature (~27°C).

- Use fresh cement from sealed bags for accurate results.

Acceptance Criteria

| Cement Type | Specific Gravity (G) | Status |

|---|---|---|

| OPC | 3.10 – 3.16 | Acceptable |

| PPC | 2.90 – 3.05 | Acceptable |

| Below 2.8 | Inferior quality | |

| Above 3.2 | Possible adulteration |

Impact of Low Specific Gravity Cement

If the specific gravity is too low, it indicates:

- Presence of moisture in cement.

- Use of expired cement.

- Adulteration with fly ash or other impurities.

- Reduced concrete strength and durability.

Advantages of Specific Gravity Testing

- Ensures cement quality before use.

- Avoids construction defects and costly repairs.

- Essential for accurate concrete mix design.

- Helps in detecting adulterated cement in India.

Frequently Asked Questions (FAQs)

1. What is the ideal specific gravity of OPC cement?

It should be between 3.10 and 3.16 as per Indian standards.

2. Why is kerosene used instead of water?

Because cement reacts with water and forms lumps, leading to incorrect results.

3. Which IS code governs the specific gravity test?

The test follows IS 4031 (Part 11):1988.

4. What if the specific gravity of cement is below 3.0?

It indicates poor-quality cement or excessive replacement materials like fly ash.

5. Is this test compulsory in India?

Yes, it is commonly performed in construction quality control laboratories for all major projects.

Conclusion

The specific gravity test of cement is a simple but crucial step in ensuring quality concrete. By following the IS 4031 guidelines, engineers and contractors can confirm whether the cement is suitable for safe and durable construction.

In Indian construction practices, using high-quality cement directly affects the strength, stability, and lifespan of structures. Performing this test helps avoid structural failures and ensures compliance with building codes.

Author- Ayush