(Tailored for Indian civil engineering students, professionals, and exam aspirants)

Introduction

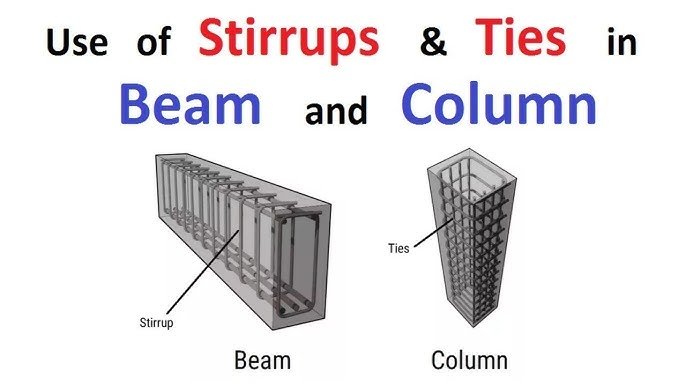

In civil engineering and construction projects, safety and stability are the most important factors. When designing reinforced concrete structures (RCC), engineers focus not only on strength but also on durability and safety. One key component that plays an important role in this is stirrups.

Stirrups are closed-loop reinforcements made of mild steel bars or rebars that hold the longitudinal reinforcement bars (main bars) in position. They are commonly used in beams, columns, and other RCC structures to provide shear strength and prevent buckling of the main reinforcement.

In this article, we will discuss:

- The purpose of using stirrups

- Their types, placement, and design considerations

- IS codes related to stirrups

- Tables showing stirrup spacing

- Practical tips for site engineers

- FAQs for interviews and exams

This detailed guide is optimized for the Indian audience preparing for civil engineering interviews, PWD exams, GATE, SSC JE, and site work.

What Are Stirrups in RCC Construction?

Stirrups are small, closed steel ties that enclose the main reinforcement bars in beams and columns. They are usually made from mild steel or high-strength deformed bars.

Functions of Stirrups:

- Hold longitudinal bars in position.

- Resist shear forces.

- Prevent buckling of compression bars.

- Distribute loads evenly.

- Improve ductility and earthquake resistance.

In India, IS 456:2000 provides detailed guidelines for stirrup spacing, diameter, and placement.

Also Read Maximum Bearing Capacity of Soil

Main Purpose of Using Stirrups

| Purpose | Explanation |

|---|---|

| Shear Resistance | Stirrups take the diagonal tensile stresses caused by shear forces and prevent cracks. |

| Hold Main Bars | They keep the longitudinal bars in their proper positions during concreting. |

| Prevent Buckling | In columns, stirrups prevent vertical bars from bending or buckling under heavy loads. |

| Improve Ductility | Structures become more flexible, especially during earthquakes. |

| Crack Prevention | Reduce diagonal and horizontal cracks in beams and columns. |

| Load Distribution | Help transfer loads effectively between different structural components. |

Why Stirrups Are Crucial in RCC Beams and Columns

In RCC beams and columns, two main forces act:

- Bending moments → handled by longitudinal bars

- Shear forces → handled by stirrups

Without stirrups, diagonal cracks would form, leading to sudden structural failure. For earthquake-resistant construction, IS codes make stirrups mandatory in critical regions.

Types of Stirrups Used in Construction

| Type | Shape | Application |

|---|---|---|

| Single-Legged | “U” shape | Light loads, rarely used in RCC beams. |

| Two-Legged | Rectangle | Common in small beams and columns. |

| Four-Legged | Square | Used in large columns with higher loads. |

| Six-Legged | Hexagonal | For heavy-duty columns in high-rise buildings. |

| Circular | Round loops | Preferred in circular columns, water tanks, and chimneys. |

| Helical | Spiral | Used in seismic zones for maximum ductility and confinement. |

Standard Stirrup Spacing (IS 456:2000)

IS 456:2000 recommends specific stirrup spacing depending on shear forces and beam depth.

| Location | Maximum Spacing | Notes |

|---|---|---|

| Near supports | d/4 | High shear region, spacing is reduced. |

| Mid-span | d/2 | Lower shear, spacing can be increased. |

| Minimum stirrups | ≤ 300 mm | Even if shear is low, spacing ≤ 300 mm. |

| Seismic zones | ≤ 100 mm | Close spacing recommended. |

Note:

d = effective depth of beam.

IS Code Recommendations for Stirrups

- IS 456:2000 → Main code for RCC design.

- IS 13920:2016 → Guidelines for earthquake-resistant construction.

- IS 1786:2008 → High-strength deformed bar specifications.

Calculation of Stirrups

For interview and exam preparation, you should know the basic formula:

Shear strength (τc) = Vc / b × d

Where:

- Vc = Shear capacity

- b = Beam width

- d = Effective depth

When τc exceeds permissible values, closer stirrup spacing is required.

Importance of Stirrups in Seismic Design

In earthquake-prone regions, stirrups provide:

- Higher ductility → absorbs seismic energy.

- Confined concrete core → prevents crushing.

- Avoids brittle failure → ensures life safety.

For Zone IV & V areas in India, closely spaced stirrups are mandatory near beam-column joints.

Practical Guidelines for Site Engineers

| Tip | Details |

|---|---|

| Bar Diameter | Use 8 mm or 10 mm stirrups for beams. |

| Spacing Control | Reduce spacing near supports. |

| Bending Hooks | Always provide 135° hooks as per IS code. |

| Overlap | Maintain a minimum overlap of ≥ 10d. |

| Check During Shuttering | Ensure stirrups hold bars firmly before concreting. |

Applications of Stirrups

- Residential buildings

- Bridges and flyovers

- High-rise towers

- Industrial structures

- Water tanks and chimneys

Stirrups ensure that beams and columns remain safe under shear loads and earthquakes.

FAQs

1. What is the main purpose of stirrups in RCC beams?

Stirrups resist shear forces and prevent diagonal cracking in beams.

2. What is the difference between stirrups and ties?

Both are similar, but stirrups are used in beams, while ties are used in columns.

3. What hook angle is used in stirrups as per IS code?

IS 2502 recommends a 135° hook for better anchorage.

4. What is the minimum stirrup diameter?

8 mm → For beams

6 mm → For slabs

5. Which IS code specifies stirrup guidelines?

IS 456:2000 → General RCC

IS 13920:2016 → Seismic design

Conclusion

Stirrups are a small but essential part of RCC construction. They improve shear strength, prevent buckling, and make structures safer during earthquakes. Whether you are a civil engineering student, a site engineer, or preparing for PWD, SSC JE, or GATE, understanding stirrups is crucial.

For Indian construction, always follow IS 456:2000 and IS 13920:2016 guidelines to ensure safety, strength, and durability.