A footing is the lowest part of a building’s foundation. It sits in direct contact with the ground. The footing spreads the structure’s load over a wider area of soil. This prevents excessive settlement. It also keeps the building stable and upright. Footings are usually made of reinforced concrete. They are often hidden underground. Yet their role is one of the most important jobs on any construction site.

This article explains footings in plain language. It covers definitions, types, functions, design basics, steps to build footings, quality checks, Indian standards, common problems, cost drivers and practical tips for sites in India. The writing uses short sentences and full paragraphs. Tables summarise key points for quick reading. At the end you will find practical FAQs and a clear conclusion to help you plan or supervise footing work.

Quick design checklist for footings (site use)

| Item | Check before casting |

|---|---|

| Geotech report available | SBC, water table, layer depths |

| Footing level and layout | Marked with pegs and levels |

| Excavation base | Clean, compact and level |

| PCC blinding | Laid where specified |

| Reinforcement | Correct bars, spacing and chairing |

| Cover | Minimum specified (e.g., 50 mm) |

| Formwork | Aligned, tight and supported |

| Concrete grade | RMC batch ticket or site mix approved |

| Vibration | Experienced operator and vibrator |

| Curing | Plan and materials ready |

| Test cubes | Cast and labelled for 7/28-day tests |

Use this checklist at the pre-pour meeting to avoid last-minute rework. New Delhi Municipal Council

Why footings matter

Footings transfer loads from the structure to the soil safely. A wrong footing can cause uneven settlement. That leads to cracks, tilting or serious structural damage. In cities, building close to neighbours makes footing design more critical. Modern multi-storey buildings need specially designed footings. They must account for heavier loads, weak soil and groundwater. In India, where soil types vary widely over short distances, careful design and execution of footings are essential. Indian codes such as IS 456 and IS 1904 give designers rules and guidance for safe footings. Law Resource+1

Basic definition and function of a footing

A footing is the part of a foundation that contacts the earth directly. It is typically wider than the column or wall it supports. The widening reduces pressure on the soil below. The main functions are:

- To spread vertical loads from columns and walls so soil bearing capacity is not exceeded.

- To reduce differential settlement between different parts of the structure.

- To provide a solid, level platform for the superstructure above.

- To resist overturning or sliding caused by lateral forces when combined with other foundation elements.

Footings may also carry small bending moments when loads are eccentric or when two columns are close and share a common footing. Designers must consider these effects when sizing and reinforcing the footing. ultratechcement.com+1

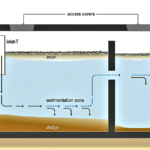

Classification: shallow vs deep foundations

Footings are part of shallow foundations when the load-bearing soil lies near the ground surface. When a safe bearing layer lies very deep, engineers use deep foundations like piles, caissons or drilled shafts. A commonly used rule of thumb is: if the depth of the footing (Df) is less than the width (B) of the footing (Df/B < 1), then the foundation may be treated as shallow. Shallow footings include isolated (pad), strip, combined and raft footings. When the soil is weak or the water table is high, piles or a piled-raft may be required. Indian practice uses site-specific geotechnical advice to choose which option is safe and economical. AQUIBZAFAR+1

Common types of footings and when to use them

Below is a practical table listing common footing types, their description, and typical applications in India.

| Footing Type | Description | Typical applications |

|---|---|---|

| Isolated (Pad) footing | Individual square or rectangular footing under single column | Low-rise buildings, columns with adequate spacing |

| Strip footing | Continuous footing under load-bearing wall | Masonry walls, small houses |

| Combined footing | One footing supporting two or more columns | Closely spaced columns or eccentric loads |

| Staircase/Sloped footing | Footing with sloping sides for stepped loads | Where stepped foundation needed on slope |

| Raft or mat footing | Large continuous slab supporting many columns/walls | Weak soils, heavy loadings, basements |

| Pile foundations | Deep vertical members transfer load to hard strata | Very soft soils, high-rise buildings |

| Pier/caisson footing | Large-diameter bored foundations | Bridges, towers, heavy loads |

| Strap footing | Two isolated footings connected by a beam (strap) | Eccentric loads or property line constraints |

Each type has pros and cons. Isolated footings are simple but need good soil bearing capacity. Raft foundations cover many columns and reduce differential settlement on soft soils. Piles move loads to deeper, stronger layers. The choice depends on soil data, loads, water table and cost. House Gyan+1

Also Read Seminar Project Topics for Civil Engineering Students — Complete Guide (India-focused)

Design basics — what engineers check

Designing a footing combines geotechnical and structural considerations. The key inputs are:

- Safe Bearing Capacity (SBC) of soil from a geotechnical report. This tells how much pressure soil can carry without excessive settlement.

- Loads from the superstructure: dead, live, wind, seismic and any eccentric loads. IS codes define load factors and combinations.

- Footing size needed to keep pressure below SBC. Area required = Vertical load / allowable soil pressure.

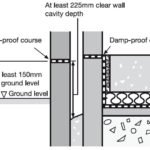

- Depth of footing to avoid frost action (not relevant in most of India), to reach competent soil and to provide proper cover. IS codes often call for minimum depths for frost, scour, or freeze; for India, a minimum embedment of about 0.5 m below ground is common for shallow foundations.

- Reinforcement for bending and shear as per IS 456 and related codes. Footings behave like shallow slabs with concentrated loads; designers check moments under columns and shear near column faces.

- Settlement estimate: permissible differential and total settlement must be within tolerable limits for the superstructure. When settlement is high, choose raft or piles.

Engineers use IS 456 for structural design rules and IS 1904 / IS 2950 / IS 12070 for foundation-specific practices. Complex projects also require finite element or soil-structure interaction analysis. Law Resource+1

Step-by-step process: how footings are constructed

A well-organised construction sequence prevents problems. The typical steps on site are:

- Site survey and layout. Mark building lines and footing centres. Use pegs, levels and coordinates.

- Excavation. Excavate to required depth. Keep sides stable and provide shoring if needed. For strip footings, dig a trench; for pad footings, excavate separate pits. Remove soft or loose soil.

- Prepare subgrade. Clean the base. Compact and lay sand or lean concrete (PCC) 50–100 mm thick as blinding. This provides a level surface and prevents contamination of the footing concrete.

- Set reinforcement. Place steel bars and spacers according to design drawings. Chairs hold bars off the blinding so concrete fully encloses them.

- Formwork (if required). For stepped or sloped footings, temporary shuttering may be used to get neat edges. Often pad footings are cast without vertical formwork.

- Concrete pouring. Pour RCC of specified grade. Use RMC when available for quality. Vibrate to avoid honeycombing.

- Curing. Keep footing moist for minimum 7 days (14 days for better strength in hot/dry conditions). Proper curing controls shrinkage and increases durability.

- Backfilling and compaction. After achieving strength, fill the excavated area with selected fill and compact in layers. Protect the footing during backfilling.

- Quality tests and records. Record concrete batch tickets. Cast cubes for strength testing. Inspect reinforcement cover and dimensions.

Following documented steps reduces errors and ensures that constructed footings match design intent and Indian codal requirements. CPWD and similar manuals give recommended practices for many of these steps. goaelectricity.gov.in+1

Reinforcement detailing and common details

Footing reinforcement prevents failure from bending and shear and controls cracking. Some practical detailing tips:

- Provide main bars in both directions for pad and raft footings. Place them as near the tension face as practical for bending stresses.

- Use distribution bars to control cracking and distribute loads.

- Provide adequate development length where bars extend into columns or grade beams. IS 456 and SP 34 provide bar bending and development rules.

- Maintain minimum cover to protect steel from corrosion — typically 50 mm cover for footings in contact with earth unless specified otherwise.

- Where columns are eccentric, check edge shear (punching shear) and provide shear reinforcement (stirrups or links) as needed.

Correct detailing and proper cover extend the life of footings and reduce maintenance. Poor detailing is a common cause of premature footing distress. Law Resource+1

Soil investigation: why it is non-negotiable

Designers must have reliable soil data. A geotechnical investigation gives:

- Soil profile and layer thickness.

- Standard Penetration Test (SPT) values or unconfined compression strength.

- Groundwater table depth.

- Soil classification and estimated bearing capacity.

- Parameters for settlement analysis and design of deep foundations if needed.

Without this information, a designer risks underestimating settlement or overloading weak layers. In urban India where buildings sit close to each other, neighbouring foundations and utilities make a proper geotechnical report essential. IS 1904 and other codes recommend minimum exploration for safe footing design. Law Resource+1

Common problems with footings and field fixes

Even with good design, field problems occur. Here are common issues and suggested fixes:

- Soft or loose base discovered during excavation. Fix by removing poor soil and replacing with compacted fill or PCC blinding. If soft layer is deep, use raft or pile solutions.

- High groundwater during excavation. Dewatering, wellpoints or switching to a pile solution may be necessary. Sheet piling or cofferdam may be used in severe cases.

- Honeycombing and poor concrete compaction. Ensure good vibration and proper RMC slump. Avoid over-watering. If honeycombing is local, patch with epoxy grout or mortar after proper cleaning.

- Rebar contamination or insufficient cover discovered. Correct before casting by re-tying bars and adding spacers or chairs. If cast incorrectly, coring and remedial concrete overlay may be required.

- Unexpected settlement after construction. Monitor and, for minor cases, underpinning or strengthening may be required. For major settlements, specialist forensic engineering advice is needed.

Timely identification and correction at site save costs compared with late repairs. Regular inspection during excavation and reinforcement checks avoid many of these problems. sefindia.org+1

Quality control and tests for footing concrete

Quality control ensures the footing achieves its intended strength and durability. Typical QC items include:

- Concrete mix verification: Check mix design or RMC plant certificate for grade and water-cement ratio.

- Slump test on site to check workability (avoid excessive water addition).

- Cube specimens for 7 and 28-day compressive strength tests per IS standards.

- Visual checks for reinforcement placement, cover, and formwork alignment before casting.

- Inspection of curing checks that water or curing compound is applied for required period.

Record test results and inspection reports in the site diary. This documentation safeguards the owner and contractor and helps resolve disputes. Law Resource+1

Cost drivers: what affects footing cost in India

Footing cost depends on many factors:

- Excavation difficulty — rock or high groundwater increases cost.

- Soil type — soft soil may force raft or piles which are expensive.

- Concrete grade and steel weight — higher grades and more reinforcement increase material cost.

- Formwork and shuttering needs — stepped or complex footings add formwork cost.

- Access and handling — tight urban sites need more labour and time.

- RMC vs site-mix — RMC gives quality but transport cost matters for remote sites.

- Testing and instrumentation — geotech and monitoring costs add to initial expense.

Early contractor involvement and value engineering usually find an economical solution that meets safety and function. A soil investigation often reduces risk of unexpected costs during construction. igs.org.in+1

Sustainability and modern practices

Modern construction emphasises sustainability. For footings, this includes:

- Use of blended cements and supplementary cementitious materials like fly ash or slag to reduce embodied carbon in concrete.

- Optimised reinforcement using better detailing to reduce steel usage without sacrificing safety.

- Recycled aggregates where local codes and quality allow.

- Efficient excavation and waste management to reduce spoil and haulage.

- Prefabricated footings for repeatable, controlled quality in industrial projects.

These practices reduce both environmental impact and lifecycle cost when carefully planned and executed. Indian guidelines and manufacturers now provide materials and technical support aligned with these goals. MDPI+1

Indian codes and references you should know

Key Indian standards and manuals relevant to footings include:

- IS 456:2000 — Plain and Reinforced Concrete Code of Practice (design and detailing).

- IS 1904:1986 — Code for design and construction of simple spread foundations.

- IS 2950 — Code on raft foundations.

- IS 12070 — Foundations on rock.

- CPWD Works Manual and Specifications — Practical execution guidance for government projects.

These documents give designers and contractors the minimum standards and recommended procedures to ensure safe and durable footings. For any project, confirm the latest editions and amendments. Law Resource+1

FAQs (Practical answers for Indian sites)

Q1: How deep should a footing be?

A1: Depth depends on soil, frost (rare in most of India), and groundwater. A minimum embedment of about 0.5 m is commonly used, but designers set the depth based on geotechnical data and local building rules. Always follow the geotech report and local bye-laws. igs.org.in

Q2: When is a raft footing preferred?

A2: Use a raft when the soil is weak and loads from columns are close together. A raft spreads loads and reduces differential settlement. It is common for basements and large commercial buildings. Law Resource

Q3: Can we use the same footing design for all columns?

A3: Not always. Heavier columns or columns near property edges may need larger or combined footings. Designers usually calculate each column load and provide footing sizes accordingly. Economy often guides grouping similar columns to standardise footing sizes. Scribd

Q4: How long should footings be cured?

A4: Minimum 7 days is standard for basic curing. For better durability, 14 days is recommended in hot or dry climates. Use water curing, wet hessian or curing compounds as per site conditions. New Delhi Municipal Council

Q5: Is RMC better than site mix for footings?

A5: RMC offers more consistent quality and controlled mix. It reduces site batching errors. For remote or small sites, site-mix may still be used when quality control is good. Choose RMC when available and affordable. Skill-Lync

Conclusion — practical takeaways

Footings are the foundation’s foundation. Good footings start with reliable soil data and clear design. They need careful excavation, accurate reinforcement detailing, quality concrete and disciplined curing. In India, variations in soil and groundwater mean designers must be conservative and builders must follow the geotech and structural recommendations closely. Using the right footing type — isolated pad, strip, combined, raft or pile — depends on soil, load, cost and constructability.

Plan footings early. Conduct or commission a geotechnical investigation. Use codal procedures (IS codes and CPWD manuals). Inspect reinforcement and covers before each pour. Keep good records of mix, cube tests and site inspection. These steps reduce risk, cost overruns and later repairs.

If you follow the steps and checks in this guide, you will build footings that protect the whole structure above. Good footings save money over the long term and keep buildings safe and serviceable for decades.