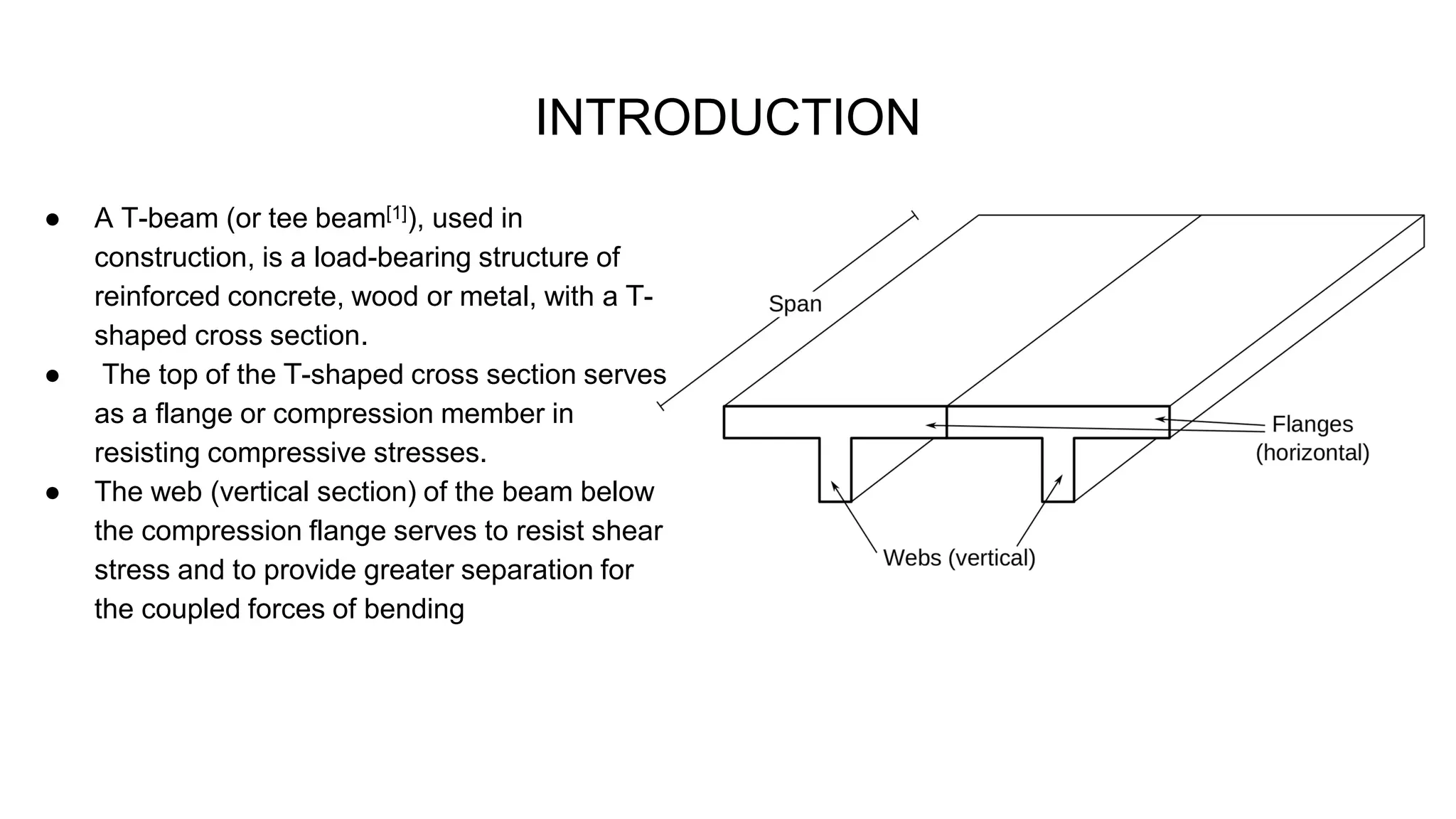

A T-beam is a common structural element in reinforced concrete and steel work. Its cross section looks like the letter “T”. The top horizontal part is called the flange. The vertical web or stem carries shear and helps bending resistance. In many slab-and-beam systems the slab itself acts as the flange. This makes the T-beam efficient. But it also brings some limits. This article explains the advantages and disadvantages of T-beams in a clear, practical way. It is written for civil engineers, site supervisors, students and Indian contractors. The language is simple. Sentences are short. The article includes tables, design notes, Indian practice tips, FAQs and a concise conclusion.

Quick snapshot — what you will learn

You will learn:

- How a T-beam works.

- Why designers choose a T-beam.

- When a T-beam is economical.

- The structural and construction drawbacks to watch for.

- How T-beams compare to other beam types (rectangular beam, I-beam, box girder).

- Practical tips for design and construction in India.

- Frequently asked questions and short answers.

I used modern references and engineering practice to make the guidance practical and current. Wikipedia+1

What is a T-beam (short definition)

A T-beam is a beam whose top portion forms a flange that resists compression. The bottom stem (web) resists shear and provides space for tensile reinforcement. When a structural slab is cast monolithically with beams, the slab becomes the compression flange. The result is a slab-and-beam system that behaves like many small T-beams spaced across the span. T-beams are used in buildings, parking garages, and bridge decks. Wikipedia+1

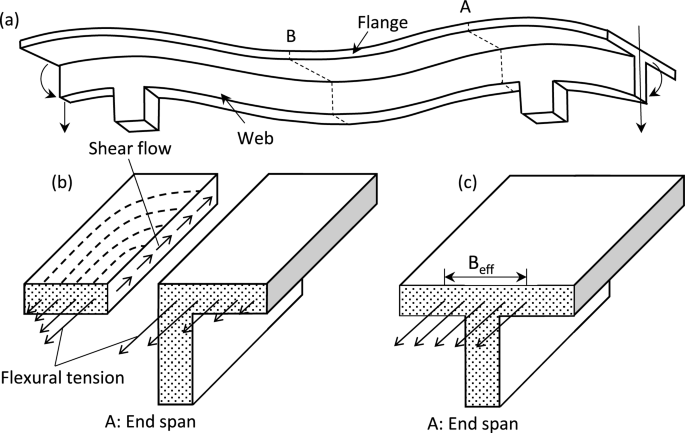

How a T-beam carries load — simple mechanics

When a beam bends under load, the top fibers go into compression and the bottom fibers go into tension. In a T-beam, the flange (top wide part) resists most of the compression. The web carries shear and allows placement of tension steel at the bottom. Because the flange is wide, the beam has a larger second moment of area (I) than a simple rectangular beam of the same depth. That increases stiffness and reduces deflection for the same material use. When the slab acts as the flange, you save concrete because you do not need a separate wide beam section. theconstructor.org

Advantages of T-beams — what they do well

Below I list the main advantages, explain each, and note where they matter most.

1. Material efficiency — less concrete for given bending resistance

T-beams use the slab as the compression flange. This saves concrete compared with a deep rectangular beam that would have to provide the same compressive area. The savings show up when spans are moderate and slab continuity is available. For buildings where slab width is already required, the T-beam is a very economical choice. theconstructor.org

2. Higher bending stiffness and lower deflection

Because the flange increases the section modulus, a T-beam resists bending better than an equivalent rectangular beam of the same depth. You get lower midspan deflection for the same reinforcement and depth. That improves serviceability — less sagging, less cracking. theconstructor.org

3. Good for one-way slab systems and medium spans

T-beams are ideal where slabs span one way between ribs or beams. Typical applications are floor systems with repetitive ribs, and bridge decks made of longitudinal girders with a deck slab. For medium ranges (say a few metres to 8–10 m depending on loads) the T-beam is efficient and simple to design. ijeit.com

4. Integrates slab and beam — simpler load path

When slab and beam are monolithic, the load path is continuous. Shear flow between slab and web is managed by the monolithic connection. This reduces the need for a very wide isolated beam. Construction is often faster because slab and beam pour together in one stage. Rural Development Department Tamil Nadu

5. Reduced formwork volume in some systems

If the slab itself is the flange, you avoid building a large separate beam form. For ribbed slabs (a series of T sections) the amount of formwork compared to separate wide beams can be lower. This is a practical savings on labour and shuttering material for repetitive building floors. ijeit.com

6. Useful in bridge decks and parking structures

T-beam bridges and T-beam decks are common because they combine deck and supporting ribs. They are also convenient when you need openings or utilities under the deck. For many highway bridges, a T-beam arrangement with closely spaced webs gives enough transverse stiffness while being economical to cast. ijeit.com+1

7. Better architectural headroom control

Because the compression flange is the slab, T-beams can be shallower than equivalent rectangular beams for the same stiffness and strength. This saves floor-to-floor height and is useful in building design where headroom is precious. theconstructor.org

Table — Advantages at a glance

| Advantage | Why it matters | Typical application |

|---|---|---|

| Material efficiency | Uses slab as flange → less concrete | Residential/commercial floors |

| Higher stiffness | Larger section modulus → less deflection | Long spans, serviceability-critical |

| Integrates slab & beam | Monolithic cast → simple load path | Ribbed slabs, bridge decks |

| Reduced formwork | Lower shuttering cost in repetitive ribs | Multi-storey car parks |

| Saves headroom | Shallower structural depth for same stiffness | Urban buildings with limited floor-height |

| Effective for medium spans | Economic for spans where box girder is overkill | Small to medium bridges |

Disadvantages of T-beams — what to watch out for

T-beams are not perfect. The most important drawbacks are structural constraints and construction challenges. I explain each one and give practical consequences.

1. Low torsional stiffness — weak in twist

A T-section has much less torsional rigidity than closed sections (like box girders) or symmetric sections (I-beams). This means a T-beam resists twisting poorly. In bridges or slabs with significant eccentric loads or skewed geometry, torsion can be a serious issue. Engineers often add diaphragms, cross-girders or other measures to increase transverse stiffness in T-beam decks. Wikipedia+1

2. Shear concentration at web-flange junction (stress risers)

The junction between the flange and web sees high shear and principal stress gradients. This can produce cracking or even flange separation if not designed and detailed correctly. Designers must check shear at the web and provide adequate stirrups, shear reinforcement and anchorage. In some cases web stiffeners or transverse reinforcement are needed. Wikipedia+1

3. Less efficient than closed sections for very large spans

For large spans and heavy loads, box girders or plate girders are often more efficient. T-beams tend to experience larger displacements and unfavorable stress patterns when span grows. Comparative studies of bridge types show that box girders outperform T-beams for long spans in strength, torsion and buckling resistance. This is one reason modern long-span bridges use boxes or continuous prestressed members. Jetir+1

Also Read Fast & Accurate Wall Quantity Estimation: Long Wall and Short Wall Method Explained

4. Limited bottom flange — tensile reinforcement only

Unlike steel I-sections that have a bottom flange to carry tension in bending, a reinforced concrete T-beam relies on tensile steel placed in the web. There is no concrete bottom flange to help in tension. In heavy tension zones this must be compensated by larger steel and careful anchorage. This can increase congestion of reinforcement in the web. Wikipedia

5. Complex shuttering and propping for ribbed systems

Ribbed T-beam floors require repetitive narrow web formwork and often temporary props until the concrete gains strength. For deep ribs or long spans, the formwork cost and shoring time can be significant. Prefabricated or precast solutions can reduce the pain, but that adds logistics and capital cost. ijeit.com

6. Harder to repair and retrofit

When the flange is the slab surface used for finishes, repairs to the beam web or internal reinforcement require breaking into the slab. That can be costly and disruptive. For heavily used structures (parking decks, industrial floors) maintenance becomes more intrusive compared to replaceable steel elements. theconstructor.org

Table — Disadvantages at a glance

| Disadvantage | Impact on design/construction | Common mitigation |

|---|---|---|

| Low torsional stiffness | Poor twist resistance on skewed loads | Use cross-girders, diaphragms, box sections |

| Shear at web-flange junction | Risk of local cracking | Provide shear reinforcement, web stiffeners |

| Not ideal for very long spans | Higher deflection, instability | Use box girder or prestressed members |

| No bottom flange | Heavy tension needs more steel | Careful detailing, increased reinforcement |

| Complex formwork/construction | More shoring time and labour | Precast ribs, modular formwork systems |

| Hard to repair | Slab repairs disrupt finishes | Design for access, use inspection pockets |

T-beam vs other beam types — practical comparison

Use the right beam for the job. The table below compares T-beams with rectangular beams, I-beams (steel), and box girders.

| Feature | T-beam | Rectangular RC beam | Steel I-beam | Box girder |

|---|---|---|---|---|

| Best span range | Medium | Short to medium | Medium to long | Long spans |

| Material use | Efficient with slab flange | More concrete needed | High strength steel | Very efficient for torsion/long span |

| Torsion resistance | Low | Low | Moderate | High |

| Constructability | Good for cast-in-situ rib slabs | Simple | Prefab, needs connections | Complex fabrication, high cost |

| Maintenance | More intrusive | Easier | Replaceable sections | Difficult but durable |

| Cost (typical) | Economical for many floors | Low for small spans | Costly material | High initial cost, efficient long-term |

This quick guide helps choose the system depending on span, budget and maintenance needs. For many Indian multi-storey buildings, T-beams are a sweet spot between material efficiency and construction practicality. For long highway bridges, box girders or prestressed T-girders are often preferred. Jetir+1

Design and detailing notes (practical for Indian practice)

If you choose T-beams, keep these rules in mind:

- Check shear at the web-flange junction carefully. Use shear reinforcement as per IS 456 and SP guidance. Provide adequate anchorage. gpims.wb.gov.in

- Avoid excessive slab drop below beam tops during stops in concreting. Follow cold-joint rules; if slab and ribs are cast separately, ensure proper shear keys or roughness. Rural Development Department Tamil Nadu

- Control reinforcement congestion in the web. Use distribution bars or bundled bars with spacers so concrete compaction is possible.

- Consider camber if deflection is critical. For long spans, cambering during formwork reduces visible sag after losses. Indian practice often specifies camber allowances. Indian Railways ECR

- Provide adequate inspection access for future repairs. Consider removable screed panels or inspection openings in service structures.

- Use cross girders or diaphragms in bridge decks to reduce torsion and distribute wheel loads. T-beam bridges usually have cross beams at intervals to obtain transverse stiffness. ijeit.com

Following these practice points reduces structural and execution risk.

Construction methods — cast-in-situ vs precast T-beams

Cast-in-situ T-beams are common in building floors. You cast ribs and slab together. This gives good monolithic behaviour. It needs shuttering and propping until the concrete cures.

Precast T-beams are used in bridges and industrial floors for speed. Precast ribs are manufactured offsite, transported and erected. Connections and bearing details must be carefully designed. Precasting reduces site shuttering and can improve quality, but needs handling equipment and transport planning. Precast T-beams are often prestressed for better flexural performance and to reduce cracking. ijeit.com+1

Cost factors and economy in India

T-beams are often cost-effective for typical Indian buildings for several reasons:

- Slab acts as flange → less concrete in individual beams.

- Efficiency suits repetitive floor plates used in apartment and office blocks.

- Labour-intensive shuttering is offset by repeated use on multi-floor projects.

However, final economy depends on local labour rates, shuttering material cost, availability of formwork systems, and whether precast units can be sourced. For bridges, decision between T-beam and box girder is more complex and includes lifecycle and maintenance costs. Localised studies show T-beam bridges are economical for medium spans, but for long spans box girders or prestressed concrete often win on technical grounds. Jetir+1

Durability, maintenance and lifecycle notes

T-beams are durable if detailed and built well. Key maintenance concerns:

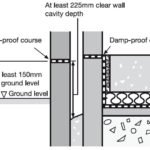

- Protect reinforcement from corrosion. Adequate cover, good concrete compaction and waterproofing minimize rust.

- Repair hairline cracks early. Cracks often form at high stress zones near web-flange junctions. Use epoxy injection or resin grouts when needed.

- Monitor for shear cracks. Diagonal shear cracks demand retrofit with external bonding or added shear reinforcement.

- For bridge decks, monitor for potholes and local delamination. Timely patching and waterproof membranes extend life.

Design for inspection access where heavy service traffic is expected. Good construction quality reduces long-term repair costs. theconstructor.org

Case study notes — typical Indian uses

- Multi-storey residential and commercial floors commonly use ribbed floor systems with T-beam action. They are economical and easy to execute with conventional formwork and props.

- Small to medium bridges across rural and semi-urban India are often designed as T-beam bridges where spans are moderate and construction methods are local. These bridges are economical and quick to build. ijeit.com+1

Local agencies and municipal design manuals often include standard drawings and spacing for T-beam ribs for typical building and bridge use.

FAQs — short practical answers

Q1: When should I choose a T-beam over a rectangular beam?

A: Choose a T-beam when the slab can act as the flange and when spans are medium. This saves concrete and reduces deflection. Use rectangular beams for short spans or where slab continuity is not available.

Q2: Are T-beams good for earthquake zones?

A: T-beams can be used in seismic regions if detailing follows ductility and confinement codes (IS 13920) and connections to slab and columns are strong. Provide proper shear reinforcement and ensure continuity of reinforcement for ductile behavior.

Q3: How do I control shear cracks in a T-beam?

A: Design for shear using code procedures. Provide vertical stirrups, bent-up bars and web stiffeners. Monitor during construction and avoid overloading during formwork removal.

Q4: Can I precast T-beams and then cast a slab in situ?

A: Yes. Precast T-beams with in-situ topping combine speed and monolithic action if composite action is ensured by shear connectors or roughened interfaces.

Q5: Do T-beams need special formwork systems?

A: Ribbed T-beam floors benefit from modular or reusable formwork systems. Proprietary system formwork reduces labour and speeds up repetitive casting.

Final checklist — good practice when using T-beams

- Confirm slab will act as compression flange before finalizing T-beam use.

- Check torsion and transverse stiffness needs; add diaphragms if needed.

- Design shear at web-flange junction explicitly.

- Avoid reinforcement congestion in webs; use spacers.

- Plan formwork, camber and propping sequence before pour.

- Consider precast options for speed and quality if logistics allow.

- Implement corrosion protection and waterproofing on deck surfaces.

- Include inspection openings for maintenance where service access is required.

Conclusion — pick the right tool for the job

The T-beam is a practical and widely used structural solution. It gives material efficiency, good bending resistance, and economy in many building and bridge applications. It is especially well suited to medium spans and ribbed slab systems, which are common in India. Yet T-beams have limits: low torsional stiffness, shear concerns at the web-flange junction, potential reinforcement congestion, and higher formwork or propping needs. For very long spans, complex torsion demands or heavy eccentric loads, closed sections like box girders or prestressed alternatives often perform better.

Good engineering judgment matters. Use T-beams where slab continuity and repetitive spans allow savings. Apply careful shear and torsion checks, and pay attention to detailing and construction practice. With the right design and site execution, T-beams deliver an economical, durable, and practical solution for many Indian projects.