The slump test is one of the most common workability tests for fresh concrete in construction. It is simple, quick, and widely used on construction sites to check the consistency and fluidity of concrete before placing it in formwork. In India, this test is essential for ensuring quality control in concrete works, especially in large infrastructure projects like bridges, roads, and buildings.

This article explains the slump test procedure, its advantages, limitations, factors affecting results, and the types of slump observed in practice.

What is a Slump Test?

The slump test is a field test used to measure the workability and consistency of fresh concrete. It helps determine whether the water-cement ratio and mix proportions meet design requirements.

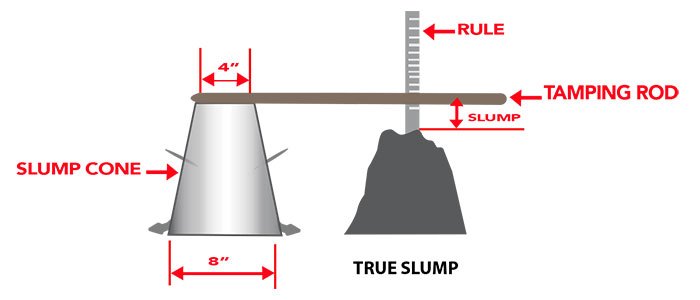

The test is conducted using a slump cone (Abrams cone) and measures the vertical settlement of concrete when the cone is removed.

Workability is essential for easy placing, compaction, and finishing of concrete without segregation or bleeding.

Purpose of the Slump Test in Construction

The main purposes of performing a slump test are:

- To check the workability of fresh concrete.

- To verify uniformity between different batches of concrete.

- To ensure proper water-cement ratio is maintained.

- To detect any variation in concrete consistency during production.

- To ensure concrete meets site-specific construction requirements.

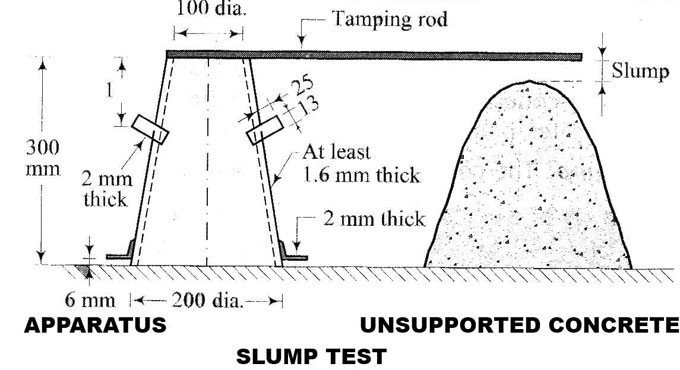

Apparatus Required for Slump Test

The following equipment is used for performing the slump test:

| Apparatus | Specification |

|---|---|

| Slump cone | Height: 300 mm, Bottom dia: 200 mm, Top dia: 100 mm |

| Base plate | Rigid, non-absorbent, preferably metal |

| Tamping rod | 16 mm diameter, 600 mm length, rounded ends |

| Measuring scale | For slump height measurement |

| Scoop | For placing concrete in the cone |

Slump Test Procedure (Step-by-Step)

The slump test procedure is described in IS 1199:1959 for Indian construction practices.

- Preparation

- Clean the slump cone and base plate.

- Ensure the cone is moistened before use.

- Place the cone on a flat, rigid surface.

- Filling the Cone

- Fill the cone in three equal layers of fresh concrete.

- Each layer should be about one-third the cone height.

- Tamping

- Tamp each layer 25 times using the tamping rod.

- The strokes should be uniform and cover the full cross-section.

- Levelling the Top

- After the last layer, level the surface using the tamping rod.

- Lifting the Cone

- Carefully lift the cone vertically upwards without twisting.

- Allow the concrete to settle freely.

- Measurement of Slump

- Measure the vertical difference between the top of the cone and the top of the slumped concrete using a scale.

- This value is the slump value in millimeters.

Also Read Working Stress Method vs Limit State Method in RCC Design – Key Differences Explained

Types of Slump in Construction

During testing, three main types of slumps may occur:

| Type of Slump | Description | Indication |

|---|---|---|

| True Slump | Concrete settles evenly without collapse. | Good workability and uniform mix. |

| Shear Slump | Concrete slips sideways with part collapse. | Lack of cohesion; may need mix adjustment. |

| Collapse Slump | Concrete completely falls apart. | Excessive water content; too high workability. |

Slump Test Values for Different Types of Construction

| Type of Construction | Recommended Slump (mm) |

|---|---|

| Mass concrete (low workability) | 25 – 50 |

| Normal reinforced concrete | 50 – 100 |

| Slip formwork and pavement works | 25 – 75 |

| Pumped concrete | 75 – 150 |

Advantages of the Slump Test

- Simple and quick to perform on-site.

- Requires no advanced laboratory equipment.

- Provides an immediate indication of workability.

- Helps maintain quality control in construction.

- Useful for comparing different concrete batches.

Recommended Slump Values for Different Concrete Mixes:

| Types Of Concrete | Slump Range( In mm) |

|---|---|

| Heavy mass construction | 20-25 |

| Pavements | 20-30 |

| Bridge deck | 25-75 |

| Beams and slabs | 50-100 |

| Columns, retaining walls and thin vertical members, etc. | 75-150 |

| Vibrated concrete | 12-25 |

Limitations of the Slump Test

- Not suitable for very dry or very wet mixes.

- Only indicates workability, not strength or durability.

- Results can be affected by operator error.

- Cannot measure segregation or bleeding.

- Not accurate for harsh mixes used in heavy-duty construction.

Factors Affecting Slump Test Results

- Water-cement ratio: Higher water content increases slump.

- Aggregate size and shape: Rounded aggregates improve workability.

- Mix proportions: Changes in sand and cement content affect results.

- Temperature: High temperatures can reduce slump.

- Time after mixing: Delayed testing reduces workability.

IS Code for Slump Test in India

In India, the slump test is performed as per IS 1199:1959 – Methods of Sampling and Analysis of Concrete. This code specifies apparatus dimensions, procedures, and guidelines for accurate testing.

Key references (standards and practical guides)

- IS 1199, Fresh Concrete — Methods of Sampling, Testing and Analysis (Part 2: Determination of Consistency). SRC- Internet Archive

- ASTM C143 / C143M — Standard Test Method for Slump of Hydraulic-Cement Concrete.SRC- ASTM International | ASTM

- Practical lab and site guidance documents from construction labs and research centres.

Conclusion

The slump test is a vital tool for quality control in concrete construction. It is widely used in India for ensuring concrete has the right workability for placement, compaction, and finishing. While it has some limitations, its simplicity and quick results make it the go-to method for most site engineers. By maintaining the right slump values, construction projects can achieve better durability, structural strength, and long-term performance.

FAQs on Slump Test in Construction

Q1. Why is the slump test important in construction?

It ensures the concrete has the right workability for easy placement and compaction.

Q2. What is the ideal slump value for RCC work?

Typically, 50–100 mm is recommended for reinforced concrete.

Q3. Can the slump test determine concrete strength?

No, it only measures workability, not compressive strength.

Q4. Which IS code covers the slump test procedure?

IS 1199:1959 specifies the method for conducting the slump test in India.

Q5. What causes a collapse slump?

Excess water content or very high workability leads to collapse slump.