Shoring is a core safety and engineering practice on construction sites. It means giving temporary support to structures, excavations, or unstable soil. Shoring prevents collapses and keeps workers safe. It also allows builders to work near existing buildings, dig deep basements, or make structural changes without risking failure. This article explains shoring in simple language. It covers the main types, common applications in India, advantages, design and execution best practices, safety and legal requirements, and a practical checklist you can use on site. Short sentences keep readability high. Everything is written for Indian builders, engineers, contractors, and homeowners who want to understand modern shoring practice.

What is shoring — the plain meaning

Shoring is the process of supporting a building, wall, trench, or other structure with temporary props or supports. These supports carry loads that the permanent structure cannot carry during construction or repair. Shoring systems can be simple timber braces for a short job. Or they can be engineered systems such as sheet piles, soldier piles, or hydraulic shores used for deep excavation or complex urban projects. In all cases, the goal is to protect lives, adjacent property, and the work itself while permanent structures are formed or repaired. UltraTech Cement+1

Why shoring matters in India today

India’s urban growth has increased the need for deep basements, metro tunnels, and adjacent construction in tight sites. Many projects must dig near existing buildings and utilities. This raises the risk of settlement, wall collapse, and service disruption. Shoring lets contractors carry out such works safely. Shoring also speeds up work by enabling safer, faster excavation and by allowing simultaneous activities near the support line. Finally, shoring helps meet legal and safety requirements that are often mandatory for deep excavations and trenches. Proper planning and specialist execution reduce the chance of accidents and costly rework. Construction Today+1

Main types of shoring (summary table)

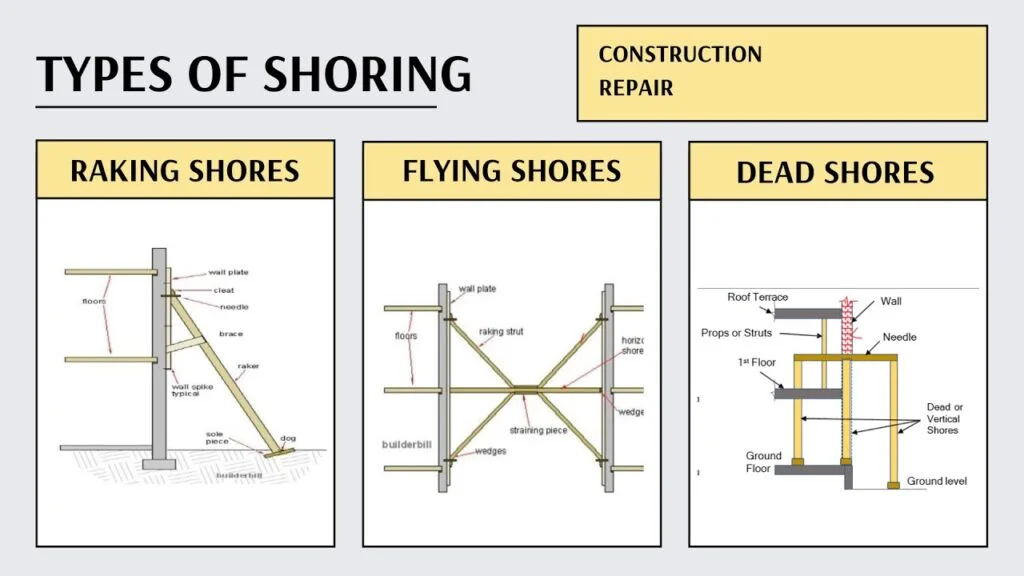

There are many shoring methods. Some are simple. Others are sophisticated and engineered. The table below lists the common types you will see on Indian projects.

| Shoring Type | Short Description | Common Use |

|---|---|---|

| Raking shoring | Inclined shores (props) support walls from outside. | For shallow excavations and temporary support of walls. |

| Dead shoring | Vertical posts carry loads from slabs/columns during repairs. | Under floors or roofs during demolition/repair. |

| Flying shoring | Horizontal props span across an opening. | Support adjacent walls during removal of a central wall. |

| Soldier piles & lagging | Steel H-piles driven and filled; timber or concrete lagging between piles. | Deep excavations next to roads or buildings. |

| Sheet piling | Interlocking steel sheets driven to form a wall. | Waterfronts, deep excavations, controlling groundwater. |

| Contiguous / secant piles | Bored piles in a line forming a retaining wall. | Very deep basements in urban sites. |

| Hydraulic shoring | Adjustable hydraulic props and plates. | Trench safety and quick shore installations. |

| Timber shoring | Timber posts, wales and struts. | Small jobs and low-cost temporary works. |

| Trench boxes (shield) | Rigid metal boxes protecting workers in trenches. | Utility works and pipeline trenches. |

| Pit and beam shoring | Beams across the pit support props below. | Large excavations where floor loads transferred. |

This list captures practical options and the contexts where they are best used. For complex urban basements, engineers prefer soldier piles, sheet piles, or secant piles because they handle deep loads and groundwater. For quick utility trenches, hydraulic shores and trench boxes are preferred because they are fast and safe. UltraTech Cement+2North Construction+2

How shoring systems work — key components

Shoring systems use a set of coordinated parts. These parts vary by type but the basic elements are similar:

- Vertical members (posts or piles): carry vertical loads from slabs, walls or soil.

- Horizontal members (wales or beams): distribute the load across vertical members.

- Struts or braces: resist lateral loads and keep the wales apart.

- Sheathing or lagging: provides the face that retains soil (timber, steel sheet, concrete).

- Anchors and tiebacks: transfer lateral loads to the stable ground away from the excavation.

- Base plates and footings: spread loads and stabilize props.

A correct shoring design balances all these parts so they act together. That prevents unequal load transfer, which can cause a collapse or excessive settlement. Engineers check loads, soil type, groundwater, adjacent structures, and construction sequences before choosing a system.

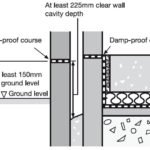

Also Read Choose the Right DPC Material in India: A Practical Guide to Damp Proof Course Selection

Applications of shoring in Indian construction

Shoring is used across many construction situations in India:

Deep basements and underground parking. Modern high-rise and commercial buildings often have multi-level basements. Shoring supports excavation walls and controls groundwater while basement slabs and retaining walls are cast. Soldier piles, contiguous piles, sheet piles, and secant piles are common solutions for such jobs.

Trench digging for utilities. Water, sewer and gas lines often require trenches in urban roads. Hydraulic shores, trench boxes, and timber shoring keep workers safe and prevent road collapse.

Structural repairs and alterations. When removing load-bearing walls or repairing beams and columns, dead shoring or flying shores temporarily carry the load so the structure can be modified.

Basement underpinning and building propping. For building strengthening or underpinning near an existing foundation, raking shores and needle beams are applied.

Bridge pier and abutment works. Shoring and cofferdams are used to create dry working conditions and support formwork for piers and abutments.

Flood and waterfront works. Sheet piling and cofferdams are deployed to protect sites from water ingress during construction.

Each application demands careful design because soil properties, groundwater level, and proximity to other structures influence system choice and dimensions. UltraTech Cement+1

Design considerations: what engineers check

A shoring design is not ad hoc. Engineers evaluate many parameters before finalising a system:

Soil classification and strength. Clay, silt, sand and gravel behave differently. Cohesive soils may stand at steeper angles, while sandy soils need closer support. Geotechnical investigation reports guide shoring depth and spacing.

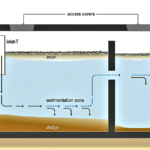

Groundwater conditions. High water tables increase lateral pressure on shoring and can cause piping. Dewatering, sheet piles, or groundwater cutoff measures may be required.

Adjacent structures and utilities. Buildings, retaining walls, trees and underground services nearby impose limits on allowable movement and settlement. Designs must keep movements within safe tolerances.

Loadings and sequencing. Live loads from traffic, storage, or cranes may affect system design. Also, the sequence of excavation and backfilling matters—temporary supports must be staged appropriately.

Materials and durability. Corrosion resistance, material strength, and fabrication quality matter. In coastal zones, choose stainless or coated systems to resist rust.

Access, erection and removal. A practical shoring design considers how the system will be installed and dismantled safely and efficiently.

Good practice is to combine geotechnical data, structural analysis and practical construction sequencing into one integrated shoring plan. geocraftbuilders.com+1

Advantages of using shoring systems

Shoring brings many benefits that go beyond safety:

Protects life and property. The most obvious benefit is preventing cave-ins and collapses. This saves lives and reduces damage to adjacent structures and utilities.

Enables deeper and safer excavations. Shoring allows construction of deep basements and complex substructures that would not be possible with sloped edges in tight urban sites.

Speeds up construction. Engineered shoring lets the team work faster and more confidently. Hydraulic and prefabricated systems cut erection time compared to traditional timber methods.

Reduces risk of settlement and litigation. Controlled shoring limits ground movement and settlement, protecting neighbouring properties and avoiding costly disputes.

Adaptable to tight urban spaces. Systems like soldier piles, secant piles, and sheet piles allow excavation close to existing buildings, which is common in Indian cities. Construction Today+1

Common mistakes and failures — what to watch for

Even with shoring, mistakes can cause serious incidents. Common problems include:

Poor site investigation. Designing shoring without full geotechnical data can underestimate lateral pressures or groundwater risk.

Inadequate tiebacks or anchors. If anchors are undersized or set into weak ground, the wall can rotate or collapse.

Improper sequencing. Removing props too early or excavating deeper than planned can overload the system.

Corrosion and weak materials. Rusted sheets or poorly welded piles can fail under service loads.

Lack of monitoring. Movement and settlement must be tracked. Ignoring early signs of displacement leads to sudden failures.

To avoid these mistakes, combine careful design, qualified contractors, good materials, and active monitoring during construction. ResearchGate+1

Safety standards and legal background (India-focused)

India has standards and guidance for safe excavation and shoring. For example, IS 3764:1992 covers safety for excavation work and gives minimum requirements for trenches and excavations. Public agencies like CPWD provide technical specifications and execution rules which include shoring practices for public works. Internationally accepted guidance such as OSHA and Caltrans manuals also informs local contractors about safe shoring and trenching procedures. Contractors in India often adopt a mix of local codes (IS and CPWD) and best-practice international guidelines for risk-critical works. Always confirm with the local municipal and state requirements as they may have additional conditions for shoring near roads and utilities. Law Resource+2भारतीय प्रौद्योगिकी संस्थान मुंबई+2

Best practices for shoring execution — step-by-step

Following best practices reduces risk and improves outcomes. The steps below are practical and aligned to modern standards.

1. Early planning and geotechnical investigation. Commission boreholes and lab tests early. Share the geotech report with the shoring designer.

2. Integrated shoring design. Have a qualified structural/geotechnical engineer produce the shoring design. Include loads, tieback spacing, and erection sequencing.

3. Permit and stakeholder coordination. Secure necessary permissions and notify adjacent owners, utilities, and traffic authorities.

4. Use prefabricated and certified materials. Avoid ad hoc timber whenever an engineered solution is required. Use certified sheets, piles, and hydraulic shores.

5. Skilled installation. Use trained crews and supervisors. Keep welding and pile-driving under qualified control.

6. Monitoring and instrumentation. Install inclinometers, settlement markers, strain gauges, and piezometers as needed. Record readings daily or per design.

7. Safe working platforms and access. Provide safe access, means of egress, and protective works such as barricades and lighting.

8. Emergency planning. Have rescue and evacuation plans. Provide rescue trays, compression devices and first-aid on site.

9. Controlled de-shoring. Remove shoring in a planned sequence, monitoring settlement and load transfer to the permanent structure.

10. Documentation and handover. Log daily checks, instrumentation data, and as-built shoring layout for future reference.

Implementing these steps strongly reduces failures and is commonly recommended in international best-practice guides. lubyshoring.com+1

Monitoring and instrumentation — why it is vital

Shoring is not a “fit-and-forget” system. Live monitoring confirms the design works as planned. Typical instruments include:

- Inclinometers to measure lateral movement of the wall.

- Settlement markers and survey points to track vertical movement of adjacent slabs or roads.

- Strain gauges on piles or wales to measure load.

- Piezometers to check groundwater pressure.

Daily or real-time monitoring helps identify trends. Early detection of excessive movement allows stopping work and reinforcing the shoring rather than suffering a large collapse. For critical sites, contractors should link alarms to supervisors and client engineers. ResearchGate+1

Material choices — timber vs steel vs hydraulic

Timber shoring is low-cost and flexible. It remains useful for very small, short-term jobs. But timber needs quality control and is not ideal for deep excavation.

Steel systems (sheet piles, soldier piles, wales, struts) are stronger and reusable. They are the standard choice for deep, urban excavations. Steel requires cranes, driving equipment, and corrosion protection in aggressive environments.

Hydraulic shoring (aluminium or steel props with hydraulic jacks) is fast and safe for trenches or where speed matters. Props are adjustable and can be installed without heavy equipment. They are ideal for utility work and rapid mobilization.

Choose materials based on depth, duration, groundwater and access. For long-term shoring, prefer steel or bored pile systems. For fast trench work, hydraulic or trench boxes are best. OSHA+1

Environmental and community considerations

Shoring can cause noise and vibration during pile driving. This affects nearby residents. Best practices include:

- Use vibrator hammers or press-in methods for low-noise pile installation when possible.

- Provide dust suppression and control runoff to avoid polluting drains.

- Monitor vibration limits to protect sensitive equipment or heritage structures.

- Provide advance notice to neighbours and businesses for major noisy operations.

Community liaison reduces complaints and the risk of legal action. For protected or sensitive areas, more conservative shoring techniques and instrumentation are often required. geocraftbuilders.com+1

Cost aspects and scheduling

Shoring costs vary widely by method, depth, soil and duration. Sheet piles and secant piles involve higher upfront costs for equipment and fabrication, but they allow deeper excavation and faster work in tight sites. Timber shoring is cheaper per unit but may be slower and less safe at depth. Contractors often calculate a life-cycle cost: equipment hire, installation time, monitoring, and removal. For big urban basements and metro projects, shoring becomes a major line item. Early contractor involvement can optimize design to reduce overall cost by selecting the most efficient shoring method for the site. geocraftbuilders.com+1

Practical on-site checklist for shoring (printable)

- Geotech report obtained and reviewed.

- Shoring design by qualified engineer in writing.

- Permits and utility clearances in place.

- Materials certified (sheet piles, props, anchors).

- Installation method and sequence documented.

- Instrumentation plan and baseline readings recorded.

- Trained crew and supervisor on site.

- Emergency rescue plan and first aid ready.

- Daily logbook and monitoring reports maintained.

- De-shoring sequence approved and monitored.

Use this checklist during pre-construction meetings and daily briefings to ensure compliance and site safety.

Case notes & lessons from incidents

Global and Indian accident analyses show trench collapses and unsupported excavations cause most shoring-related fatalities. In the U.S., trench collapses remain a major hazard despite rules. Lessons include the need for protective systems (shoring, shields), daily inspections, and not entering unsupported trenches deeper than 1.2–1.5 m without shoring. Indian project experiences also indicate that rushed de-shoring, lack of monitoring, and poor material quality lead to failures. Treat shoring as an engineered safety system, not an optional add-on. OSHA+1

Comparison table: quick selection guide

| Situation | Recommended shoring | Pros | Cons |

|---|---|---|---|

| Shallow trench for utilities | Hydraulic shoring / trench box | Fast, safe, reusable | Not for very deep cuts |

| Deep urban basement (tight site) | Soldier piles + lagging / secant piles | Handles deep excavation, minimal vibration | High cost, needs heavy equipment |

| Waterfront excavation | Sheet piles / cofferdam | Good groundwater control | Corrosion risk, requires dewatering |

| Temporary building prop / slab support | Dead shores (timber/steel props) | Simple, low cost | Limited to vertical load cases |

| Underpinning adjacent foundation | Needle beams + rakers / micropiles | Localised, precise | Requires skilled execution |

This quick guide helps match common site needs with shoring options.

FAQs (India-focused)

Q1. When is shoring mandatory for an excavation?

A1. Shoring is mandatory when excavation depth, soil type, or proximity to adjacent structures creates a risk of collapse or unacceptable settlement. Many local safety codes and IS 3764 require protective measures for trenches and deep excavations. Law Resource

Q2. Can timber shoring be used for deep basements?

A2. Timber shoring is not recommended for deep basements in urban sites. Steel sheet piles, soldier piles or secant piles are safer and more reliable for deep, long-duration works. Timber is best for shallow, short-term applications. North Construction

Q3. How do I monitor if a shoring wall is moving?

A3. Use inclinometers, settlement markers and regular visual checks. Instrumentation readings should be checked daily for critical sites. Sudden increases in movement require immediate action. ResearchGate

Q4. What is the role of tiebacks in shoring?

A4. Tiebacks (anchors) transfer lateral loads from the retaining wall into stable soil further away. They reduce bending in the wall and allow higher unsupported excavation depths. Proper testing and design of anchors are vital. UltraTech Cement

Q5. Who is responsible for shoring design and safety on site?

A5. The principal contractor is typically responsible for implementation and site safety, but a qualified geotechnical or structural engineer must design the shoring. The client and site engineer share responsibility to ensure compliance with codes and monitoring.

Conclusion — practical takeaways for Indian projects

Shoring is a safety-critical, engineered temporary works system. In India’s dense urban landscape, shoring enables deep basements, utility works and safe structural repairs. The key points to remember are: start with a good geotechnical investigation, use a qualified shoring design, choose materials suited to depth and environment, install with skilled crews, and actively monitor movements and groundwater. Adopt international best practices (such as trench box use and monitoring) together with Indian standards like IS 3764 and relevant CPWD specifications. Planning, documentation and communication with neighbours and authorities reduce risk, cost overruns, and delays. When shoring is done right, it protects people, property and programme timelines—making it one of the smartest investments on a complex construction site.

Key references and further reading

- Ultratech Cement — “Shoring in Construction: 12 Types Explained.” UltraTech Cement

- IS 3764:1992 — Code of safety for excavation work (Bureau of Indian Standards). Law Resource

- Construction Today — “7 Benefits of Shoring in Construction.” Construction Today

- OSHA Technical Manual and trenching/shoring manuals — for international best practices on shoring and trench safety. OSHA+1

- The Constructor / North Construction / industry guides — practical notes on types and uses of shoring.