Estimating wall quantities accurately saves time and money on construction projects. The Long Wall and Short Wall (LWSW) method is a simple and reliable way to measure walls for brickwork, plaster, pointing, and painting. It is widely used in India by site engineers, quantity surveyors, contractors, and students. This article explains the method in plain English. It shows step-by-step procedures, worked examples, practical tips, and common pitfalls. It also integrates useful keywords for search and practical use such as quantity estimation, BOQ preparation, construction estimating, wall quantity takeoff, brickwork estimation, plaster estimation, and building cost estimation. Short sentences and full paragraphs keep the text readable.

What is the Long Wall and Short Wall method?

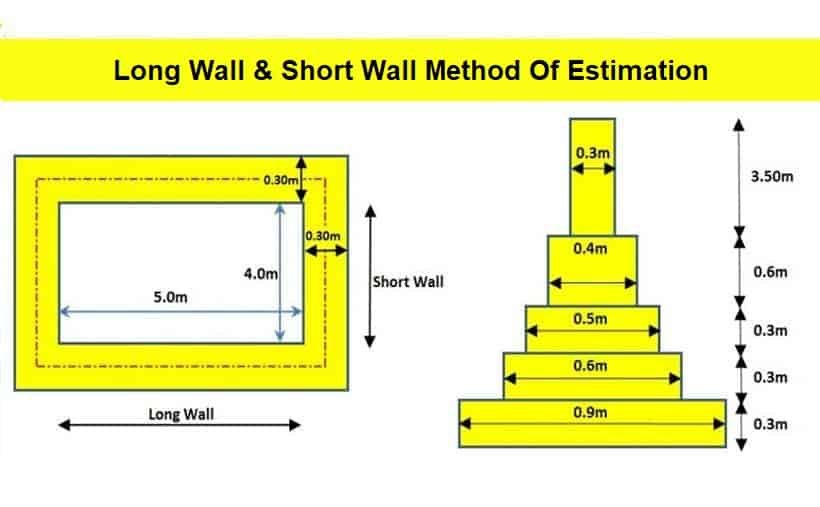

The Long Wall and Short Wall method is a manual takeoff technique used to calculate the quantities of masonry and finishes for a building. The idea is simple. You classify walls in each room as either long walls or short walls. Then you apply a small correction to the measured centre-to-centre lengths to get the effective out-to-out length for each group. The correction handles the corner overlaps automatically. After that, you multiply the effective lengths by height and thickness to get volumes or areas. This method is fast and effective for regular building plans with rectangular rooms and repeated layouts.

Why use LWSW for construction estimating?

There are several practical reasons to use the Long Wall and Short Wall method in building quantity estimation. First, it is fast. You avoid one-by-one corner deductions and repetitive arithmetic. Second, it is easy to teach and use on-site. A junior engineer can learn it quickly and produce reliable measurements. Third, it groups similar items together, which helps when preparing a bill of quantities (BOQ) or calculating material estimates for brickwork, cement-sand mortar, plaster and paints. Fourth, the method scales well for buildings with repeated room types, such as housing blocks, hostels, and office floors. Finally, it is acceptable for most preliminary and tender-stage estimates and can be supported with a centre-line or detailed check if required.

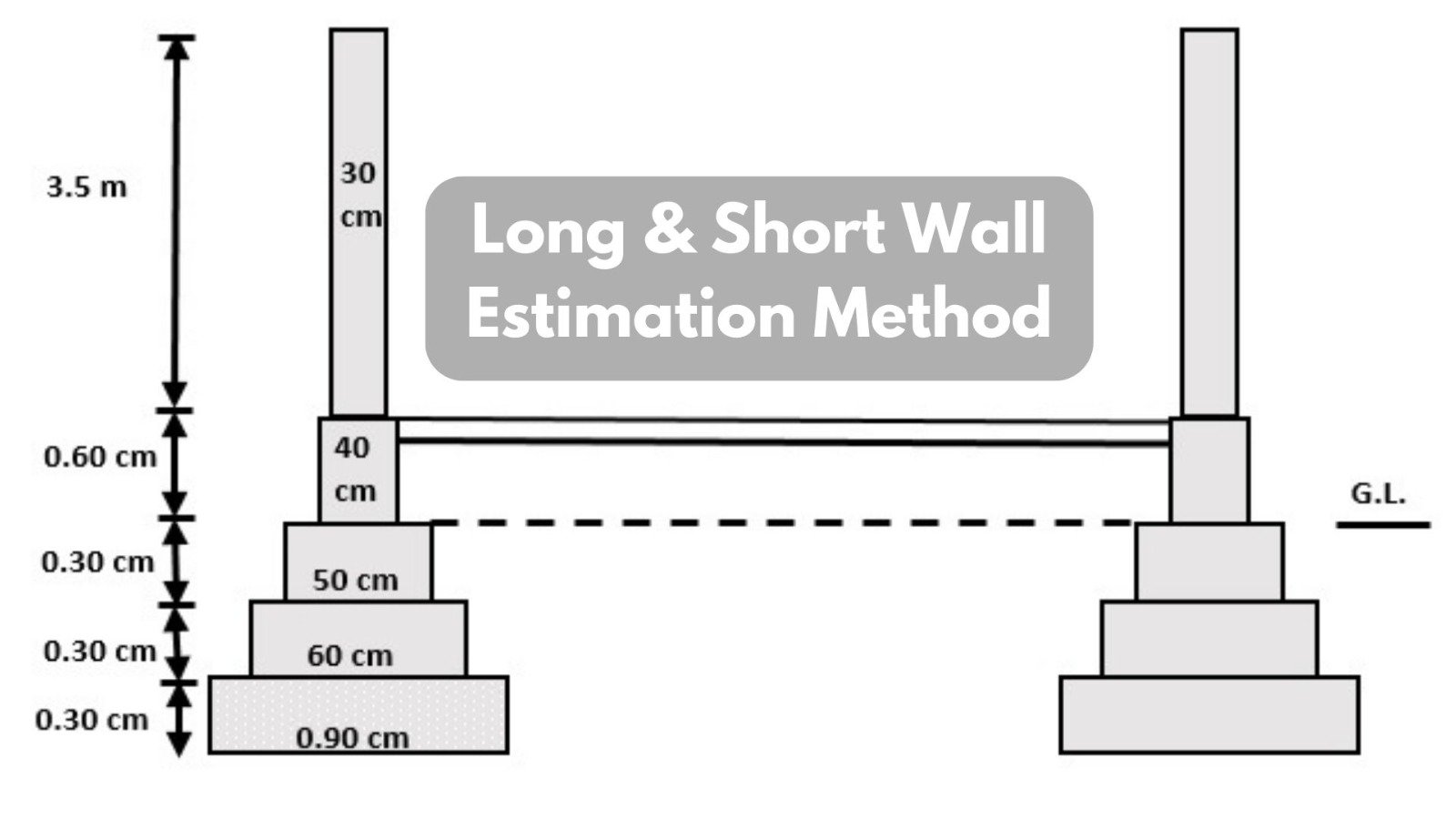

Core rules and formulae — short and precise

Before you begin the takeoff, keep these formulae in mind. They make the method quick to apply.

- Long wall effective length = centre-to-centre length + wall thickness.

- Short wall effective length = centre-to-centre length − wall thickness.

These simple corrections account for the half-thickness overlaps that occur at corners. When two walls meet, the long wall effectively gains half the thickness of the adjoining short wall at each end, adding one full thickness to the run. The short wall loses those halves and therefore reduces by one full thickness. Apply these adjustments systematically across the plan.

Also Read What Is a Sunken Slab? — Complete Guide for Indian Builders, Engineers & Homeowners

Step-by-step procedure for a correct takeoff

A careful procedure reduces mistakes. Follow these practical steps.

- Study the drawing carefully and confirm the plan scale and revision. Use the latest approved plan.

- Mark long and short walls on the plan. Long walls usually run along the longer room dimension. Use colour or annotation to avoid confusion.

- Measure centre-to-centre (c/c) lengths for each wall run. Use the plan dimensions as given. If the drawing shows finished or O/O dimensions, convert to c/c where required.

- Sum the c/c lengths of long walls for the whole building or for the set of repeated rooms. Add the wall thickness once for each continuous long run. This gives the effective long-wall length.

- Sum c/c lengths for short walls and subtract the wall thickness appropriately to get the effective short-wall length.

- Add the effective long and short lengths to get the total effective length or perimeter used for plaster, pointing or painting takeoff.

- Multiply the effective length by wall height to obtain area for plaster or painting. For brickwork volume, multiply effective length × wall height × thickness.

- Deduct the area or volume of openings such as doors, windows, ventilators. Treat lintels and jambs as separate items if needed.

- Apply wastage or contingency allowances as per local practice. Common practice is 3–5% for materials at preliminary stage and 5–10% for site ordering depending on site uncertainty.

- Cross-check totals with a centre-line method or by comparing the sum of effective lengths with the drawn perimeter to ensure reasonableness.

This disciplined workflow keeps the BOQ transparent and auditable.

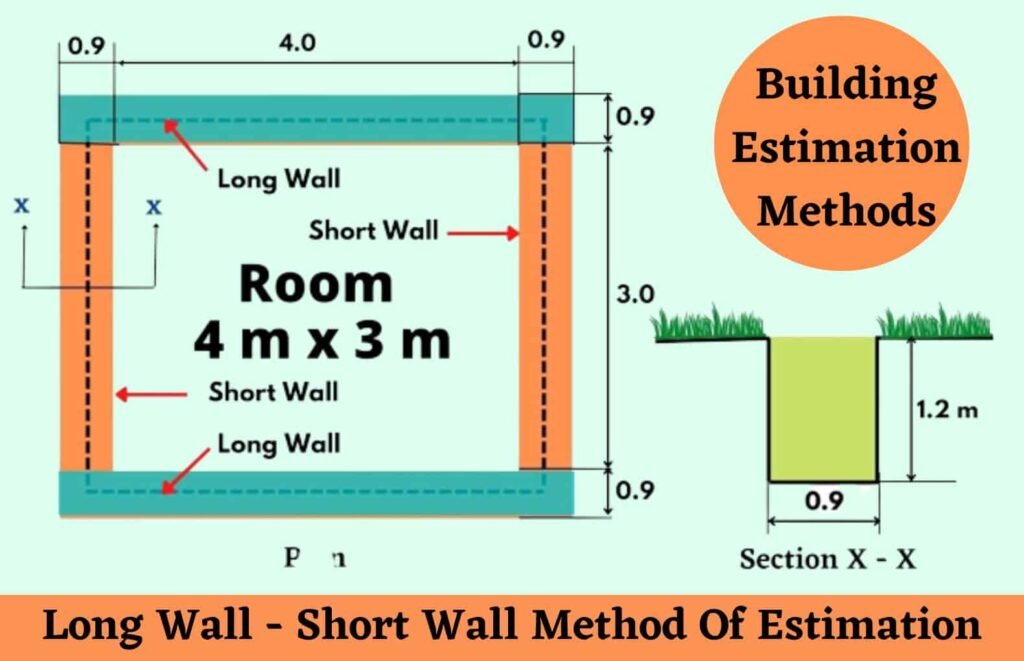

Worked example — single rectangular room

A concise example helps fix the idea. Suppose a room measures 4.00 m by 3.00 m internally. The wall thickness is 230 mm (0.23 m). Room height to the underside of the slab is 3.00 m. There is a door 0.9 m × 2.1 m and a window 1.2 m × 1.2 m.

First, mark long walls (4.00 m c/c) and short walls (3.00 m c/c). Compute effective lengths.

- Effective long wall length = 4.00 + 0.23 = 4.23 m. Two long walls give 8.46 m.

- Effective short wall length = 3.00 − 0.23 = 2.77 m. Two short walls give 5.54 m.

- Total effective length = 8.46 + 5.54 = 14.00 m.

For brickwork volume up to lintel height 2.4 m:

- Brick volume = total effective length × thickness × lintel height = 14.00 × 0.23 × 2.4 = 7.728 m³.

For plaster area:

- Gross plaster area = total effective length × height = 14.00 × 2.4 = 33.6 m².

- Openings area = door 1.89 m² + window 1.44 m² = 3.33 m².

- Net plaster area = 33.6 − 3.33 = 30.27 m².

Add a 5% wastage allowance when ordering cement and sand for plaster. This example shows how LWSW handles corner overlaps elegantly and produces usable quantities for a BOQ.

Handling openings, lintels and jambs correctly

Openings affect both plaster and masonry quantities and must be handled precisely. The common rules are:

- Deduct the area of door and window openings from plaster area. Use the actual opening width × height.

- For brickwork, deduct the volume up to the lintel level. That is, subtract opening width × lintel height × wall thickness. If brickwork above lintel exists, measure that separately.

- Lintels and chajjas are measured as separate RCC or MS items, not included in brickwork. Include bearing lengths per design.

- Jambs, reveals and rebate areas can be measured separately if the contract requires them. For preliminary estimates, you may include jambs with the plaster area if they are small.

Clear notes in the BOQ that state whether openings are deducted from plaster, masonry, or both. This avoids misunderstandings at the execution stage.

Dealing with mixed wall thicknesses and irregular plans

The LWSW method works best for plans with uniform wall thickness. When thickness varies, split the walls into groups. Apply the LWSW method separately for each thickness group and then sum the quantities. For complicated or irregular plans with many offsets, T-junctions, or curved walls, consider the centre-line method or detailed wall-wise measurement. The centre-line method adds the length of the centre lines of all walls and multiplies by cross-sectional area. It is less fiddly when many junctions exist. Use professional judgment: for simple repetitive layouts use LWSW; for irregular or architectural plans, prefer a more granular approach.

Long runs, repeated rooms and economy of scale

The LWSW method truly shines when a building repeats room layouts. For example, hostels, apartments, school blocks and row houses often have identical room dimensions repeated across floors. In such cases, measure the c/c lengths for one typical room and then multiply by the number of repeats. Add the wall thickness correction once per continuous run or as per grouping. This avoids repetitive measurement and reduces errors. For BOQ preparation, group repeated items and show quantities per unit and total for the block. Grouping helps contractors price work more accurately and simplifies procurement of bricks, cement and sand.

Comparison with centre-line and wall-wise methods

Estimators often know three standard methods:

- Long Wall & Short Wall method: Fast for regular plans. Minimal corner arithmetic.

- Centre-line method: Add centre-line lengths of all walls and multiply by cross-section. Best when walls are uniform and continuous.

- Wall-wise (face-to-face) method: Measure each wall face explicitly and deduct at corners. Most accurate but time consuming.

All three produce the same geometrical result if applied correctly. Differences arise due to rounding, handling of openings and human error. The choice depends on plan regularity, available time, complexity of the design and the purpose of the estimate (preliminary tender vs detailed execution BOQ).

Practical tips to avoid common mistakes

Estimators make avoidable errors when using LWSW. Here are practical tips that keep measurements accurate:

- Always work from the latest approved plan. Changes in wall layout or thickness are common during design.

- Clearly mark long and short walls on the plan using two colours. This avoids misclassification.

- Use centre-to-centre dimensions given on the drawing. Never guess dimensions from screen images or low-resolution prints.

- Keep separate lists for walls of different thicknesses. Apply LWSW separately for each group.

- Deduct openings in the correct item column and note whether jambs and lintels are included.

- Round only final totals. Keep intermediate calculations to two or three decimal places to avoid cumulative rounding errors.

- Cross-check perimeter totals: the sum of effective lengths should match the plan perimeter out-to-out. If not, re-check long/short markings and thickness adjustments.

- When in doubt on complex junctions, measure wall segments explicitly rather than force-fitting an LWSW correction.

Training junior staff and maintaining standard measurement templates reduces repetitive mistakes.

How to present LWSW results in a BOQ and estimate

A clean BOQ makes comparison and execution simple. Present LWSW results as follows:

- Provide a short note: “Quantities computed by Long Wall & Short Wall method; refer to measurement sheet.”

- Group items by trade: brickwork, plaster, pointing, painting, lintels and openings.

- Show the basis of measurement: wall thickness, height, and lintel levels. Include the effective lengths and the c/c lengths used.

- Separate provisional items and unforeseen works. For example, “Extra for jambs and reveals where specified.”

- Add a column for wastage and rounding rules and report final material quantities (bags of cement, sand in m³ or tonnes, bricks in numbers).

- Attach a measurement sheet or Excel workbook that shows which walls were long and short and how corrections were applied. This supports audits and helps contractors verify the takeoff during execution.

Clear presentation prevents disputes and speeds up tender evaluation.

Example: multi-room block and repetition

Consider a row of three identical rooms, each 4.0 m × 3.0 m, wall thickness 230 mm. Using LWSW you can take c/c lengths for all long walls together and add the thickness correction once for the continuous long run. For short walls internal partitions will reduce the effective length per room. Summation across the block eliminates repeated corner arithmetic. Total brickwork and plaster quantities computed this way are accurate and quick to compile. This makes LWSW very useful for housing layouts and repetitive apartment floors.

Software and digital checks

Estimators increasingly use digital tools to speed up takeoffs. Many CAD and takeoff packages let you trace centre lines and auto-compute wall areas and volumes. However, even with software, understanding LWSW is important. Use LWSW as a manual check against automated outputs. The manual method also helps when software is unavailable on site or when quick checks are needed during tender clarifications. For large projects, integrate the LWSW logic into spreadsheets or use takeoff software but document the method used so all stakeholders understand the basis of quantities.

FAQs — quick answers for common questions

Q: Does LWSW give the same result as the centre-line method?

A: Yes, if both methods are applied correctly. Differences usually come from rounding or inconsistent handling of openings.

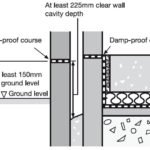

Q: How do I treat parapets and chajjas?

A: Measure parapets, chajjas, and projections separately. Do not include them in the main wall lengths.

Q: What allowance should I add for plaster wastage?

A: Typical allowances range from 3% to 5% for plaster material. For site ordering include 5%–10% depending on site conditions and accuracy of measurements.

Q: When should I not use LWSW?

A: Avoid LWSW for irregular plans, curved walls, or when many varying wall thicknesses make grouping cumbersome. Use the centre-line or detailed wall-wise method in those cases.

Q: Are openings deducted for brickwork as well?

A: Yes. For brickwork, deduct the volume of the opening up to lintel level. Lintels are measured separately.

Conclusion – practical takeaways for Indian projects

The Long Wall and Short Wall method is a proven and practical tool for wall quantity estimation. It balances speed and accuracy for regular building plans. It is especially useful for housing projects, repetitive room layouts and preliminary BOQs. To use it well, mark long and short walls clearly, measure centre-to-centre lengths carefully, handle openings and lintels correctly, and separate walls into groups when thickness varies. Always do a sanity check with the perimeter or centre-line method. Document your assumptions and show measurement sheets to keep the BOQ auditable. With proper application, LWSW streamlines construction estimating, material ordering and cost control for engineers and contractors across India.