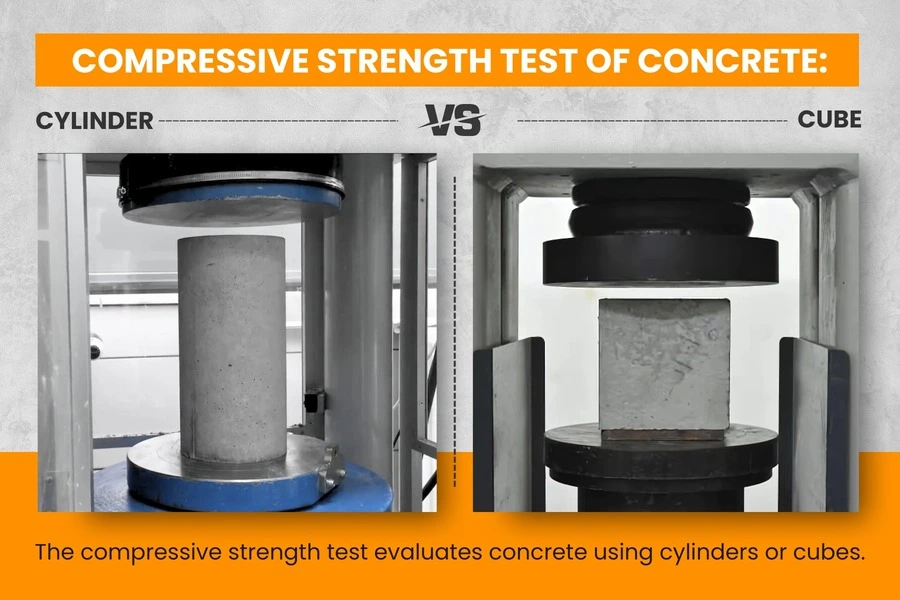

Testing the compressive strength of concrete is one of the most important quality control measures in construction. In India, this test is widely performed to ensure that the concrete mix meets the required strength as per project specifications and IS codes. The concrete cube test is the most common method used to measure this strength.

This article explains the purpose, equipment, step-by-step procedure, IS code guidelines, calculations, and common mistakes related to the concrete cube compressive strength test. It also provides tables, FAQs, and tips specifically for Indian construction practices.

What is the Concrete Cube Compressive Strength Test?

The concrete cube test is conducted to determine the compressive strength of hardened concrete. Cubes made of fresh concrete are cured for a specific period and then tested under compression.

In India, the test is performed according to IS 516:1959. This code specifies the apparatus, curing conditions, testing machine requirements, and calculation formulas.

Why is the Cube Test Important?

Concrete is the most widely used construction material in India. Its compressive strength determines its durability, stability, and safety. The cube test ensures:

- The concrete mix meets the required grade strength (M20, M25, M30, etc.).

- The structure can safely bear the load and stresses.

- Early detection of quality issues in batching or mixing.

- Compliance with IS codes and project specifications.

- Avoidance of costly structural failures.

Also Read Top Construction Tools List: Essential Tools Used in Construction

IS Codes for Concrete Cube Test

| IS Code | Description |

|---|---|

| IS 516:1959 | Methods of tests for strength of concrete |

| IS 456:2000 | Code of practice for plain and reinforced concrete |

| IS 10262:2019 | Concrete mix design guidelines |

| IS 1199:1959 | Methods of sampling and analysis of concrete |

For most projects in India, IS 516 is the primary reference.

Apparatus and Equipment Required

| Equipment | Purpose |

|---|---|

| Cube moulds (150mm x 150mm x 150mm) | To prepare concrete cubes |

| Tamping rod | For compacting concrete in moulds |

| Compression testing machine (CTM) | To apply load and measure strength |

| Curing tank | For storing cubes in water |

| Weighing balance | For accurate material proportioning |

| Vibrating table (optional) | For better compaction of concrete |

Concrete Cube Test Sample Size

- Standard cube size in India: 150mm x 150mm x 150mm

- For concrete aggregates larger than 40mm, cube size is increased to 200mm

- For small aggregate sizes, smaller cubes like 100mm may be used.

Step-by-Step Procedure of Concrete Cube Test

1. Sampling of Concrete

- Take fresh concrete samples from different batches.

- Follow IS 1199 guidelines for proper sampling.

- Mix the collected samples thoroughly before casting cubes.

2. Casting the Cubes

- Clean the moulds and apply oil to prevent sticking.

- Fill the mould in three layers, each approximately one-third of the height.

- Compact each layer using a tamping rod with at least 25 strokes.

- Level the surface and cover with a plate.

3. Curing the Cubes

- Keep the moulds undisturbed for 24 hours.

- Demould the cubes carefully and place them in a curing tank.

- Maintain water temperature at 27 ± 2°C.

- Cubes are tested after 7 days and 28 days of curing.

4. Testing the Cubes

- Remove cubes from the curing tank.

- Wipe excess water and measure their dimensions accurately.

- Place the cube in a Compression Testing Machine (CTM).

- Apply load gradually at a rate of 140 kg/cm² per minute.

- Record the maximum load applied before failure.

Calculating Compressive Strength

The compressive strength is calculated using the formula: Compressive Strength=Maximum Load (N)Cross-Sectional Area (mm2)\text{Compressive Strength} = \frac{\text{Maximum Load (N)}}{\text{Cross-Sectional Area (mm}^2\text{)}}Compressive Strength=Cross-Sectional Area (mm2)Maximum Load (N)

Example Calculation:

| Parameter | Value |

|---|---|

| Maximum Load | 750 kN |

| Cross-Sectional Area | 150 × 150 = 22500 mm² |

| Strength | 750 × 1000 ÷ 22500 = 33.3 MPa |

Acceptance Criteria (IS 456:2000)

| Grade of Concrete | Average of 3 Cubes (N/mm²) | Individual Cube (N/mm²) |

|---|---|---|

| M20 | ≥ 20 | ≥ 17 |

| M25 | ≥ 25 | ≥ 20 |

| M30 | ≥ 30 | ≥ 25 |

Common Mistakes in Cube Testing

- Improper sampling from the mixer.

- Inadequate compaction leading to voids.

- Poor curing resulting in low strength.

- Incorrect placement in the CTM.

- Using damaged or inaccurate moulds.

Best Practices

- Always prepare at least three cubes per grade of concrete.

- Use clean water and accurate proportions.

- Maintain curing temperature as per IS 516.

- Calibrate the compression testing machine regularly.

- Follow a systematic recording of results.

Advantages of Cube Testing

- Easy and reliable method for strength measurement.

- Ensures quality control at the site.

- Validates mix design performance.

- Detects faults early to avoid future failures.

FAQs on Concrete Cube Compressive Strength Test

1. What is the ideal curing period for cubes in India?

Typically, cubes are tested after 7 days and 28 days of curing. The 28-day strength is considered the standard reference.

2. What is the minimum number of cubes required per test?

At least three cubes per grade of concrete are required for each test.

3. Which IS code is used for cube testing?

The test is performed as per IS 516:1959.

4. What happens if concrete fails the cube test?

If cubes fail, engineers may require core cutting tests or adopt rectification measures like retrofitting.

Conclusion

The concrete cube compressive strength test is a crucial step in quality control for construction projects in India. Following the proper IS guidelines, using accurate equipment, and avoiding common mistakes ensure reliable results. For builders, contractors, and engineers, understanding this test is essential to deliver safe and durable structures.

By mastering this simple yet powerful test, you ensure that your concrete meets the required strength, avoids structural issues, and complies with Indian standards.