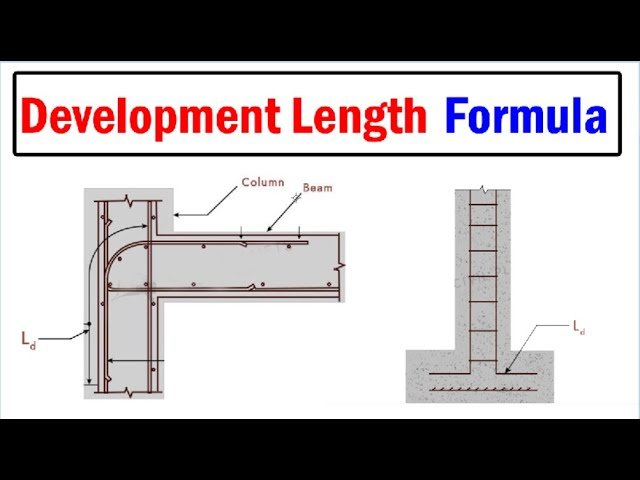

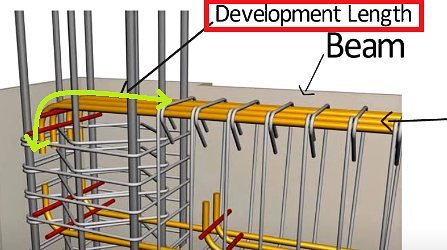

Development length is a small phrase with a big job.

It tells us how long a steel bar must be embedded in concrete.

This length makes sure the bar can reach its full strength without slipping.

In reinforced cement concrete (RCC), correct development length keeps beams, columns and slabs safe.

This guide explains the concept, the IS rules, the formula, worked examples, practical tips for India, and common FAQs.

What is development length?

Development length (Ld) is the minimum length of embedded reinforcement required to transfer stress from the steel bar to the surrounding concrete by bond. In simple words, Ld is the length of bar that must be anchored in concrete so that the bar can achieve the required tensile or compressive stress without pulling out.

If the development length is too short, the bar will slip. This leads to cracks, local failures, or loss of ductility. If it is too long, it may waste space and steel. So design codes give rules and formulas to calculate a safe, efficient Ld.

Why development length matters in RCC

- It ensures full bending or tensile capacity of reinforcement is developed.

- It prevents bar slip and premature cracking.

- It determines lap splice lengths, anchorage of hooks, and practical detailing in drawings.

- It affects fabrication, bar bending schedules, and construction sequencing.

- For earthquake-resistant design, correct anchorage is vital for ductile behavior. (See seismic detailing codes in India such as IS 13920.) Law Resource

IS 456 rules at a glance (the key clauses)

The principal Indian standard is IS 456:2000. Clause 26.2.1 gives the development length formula and guidance. The code also lists design bond stresses for plain bars in various concrete grades, and then states how to modify those values for deformed bars, compression bars, and bundled bars. Important points from IS 456:

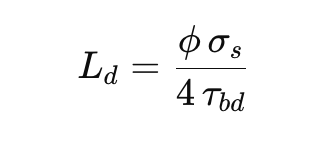

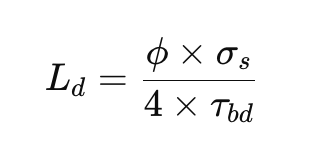

- The basic formula for Ld is:

- where φ = bar diameter; σs = stress in the bar at the section considered (design stress); τbd = design bond stress from the code. Law Resource

- IS 456 provides nominal τbd values for plain bars for concrete grades M20 to M40. For deformed bars (IS 1786), τbd is increased by 60%. For bars in compression, τbd is increased by 25%. Bundled bars require increases (10% for two in contact, 20% for three, 33% for four). Hooks and bends contribute anchorage values specified in IS 2502. Law Resource

- The code also gives practical rules for lap lengths (e.g., lap in flexural tension = Ld or 30φ whichever is greater) and staggering requirements for splices.

These IS provisions are the legal and practical baseline for RCC detailing in India. Always follow IS 456 and IS 13920 (for seismic detailing) where applicable. Law Resource

The development length formula explained

The IS formula is:

- φ (phi) — bar diameter (in mm).

- σs — stress in the reinforcement at the section under design loading. For limit state designs, this is typically σs=0.87fy\sigma_s = 0.87 f_yσs=0.87fy, where fyf_yfy is the characteristic yield strength of steel (for Fe 415, Fe 500 etc.).

- τbd — permissible design bond stress (N/mm²). IS 456 lists τbd for plain bars and prescribes multipliers for deformed bars and compression cases.

This expression comes from equating the tensile force in the bar to the shear (bond) capacity provided by the concrete over the development length.

Also Read Specific Gravity Test of Cement for Quality Concrete: Step-by-Step Guide

IS 456 design bond stress values (nominal)

IS 456 gives nominal τbd for plain bars in tension for typical concrete grades. Use these and then increase per code for deformed bars:

| Concrete Grade | τbd for plain bars (N/mm²) |

|---|---|

| M20 | 1.2 |

| M25 | 1.4 |

| M30 | 1.5 |

| M35 | 1.7 |

| M40 and above | 1.9 |

For deformed bars (IS 1786) multiply the above values by 1.6 (i.e., increase by 60%). For bars in compression, increase the tension value by 25%. These clauses are from IS 456. Law Resource

Quick multipliers: Ld as multiples of bar diameter

Using σs = 0.87fy and τbd (with the 1.6 factor for deformed bars), the formula simplifies to a multiplier times φ. The multiplier depends on concrete grade and steel grade. The table below uses σs = 0.87fy and τbd increased for deformed bars:

| Concrete Grade | τbd (deformed) N/mm² | Multiplier ≈ Ld/φ (for Fe415, fy=415) | Multiplier ≈ Ld/φ (for Fe500, fy=500) |

|---|---|---|---|

| M20 | 1.92 (1.2×1.6) | 47 | 51 |

| M25 | 2.24 (1.4×1.6) | 44 | 49 |

| M30 | 2.40 (1.5×1.6) | 42 | 46 |

| M35 | 2.72 (1.7×1.6) | 37 | 43 |

| M40 | 3.04 (1.9×1.6) | 33 | 39 |

How to read: For Fe415 in M20 concrete Ld ≈ 47φ. So a 16 mm bar needs about 47×16 = 752 mm of embedment to develop full stress. These practical multipliers are commonly used on Indian sites. (Calculations based on IS 456 formulas.) Law Resource

Worked examples (practical)

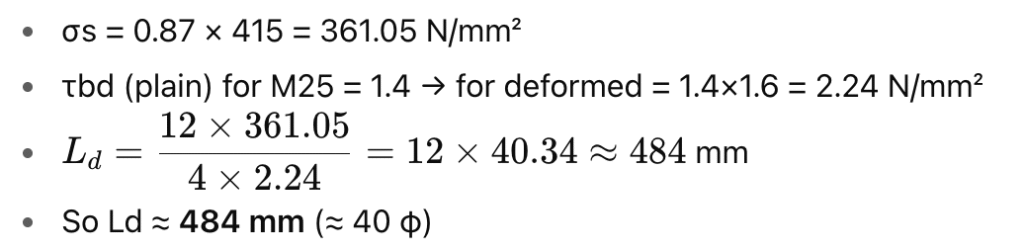

Example 1 — Fe415, φ = 12 mm, M25 concrete

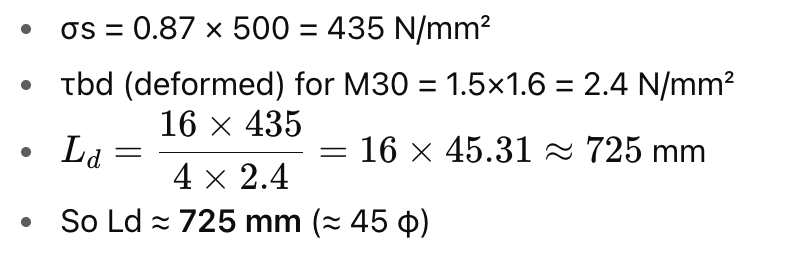

Example 2 — Fe500, φ = 16 mm, M30 concrete

These examples match common tables used by site engineers and help set bar extension and lap lengths. Law ResourceThe Civil Engineering

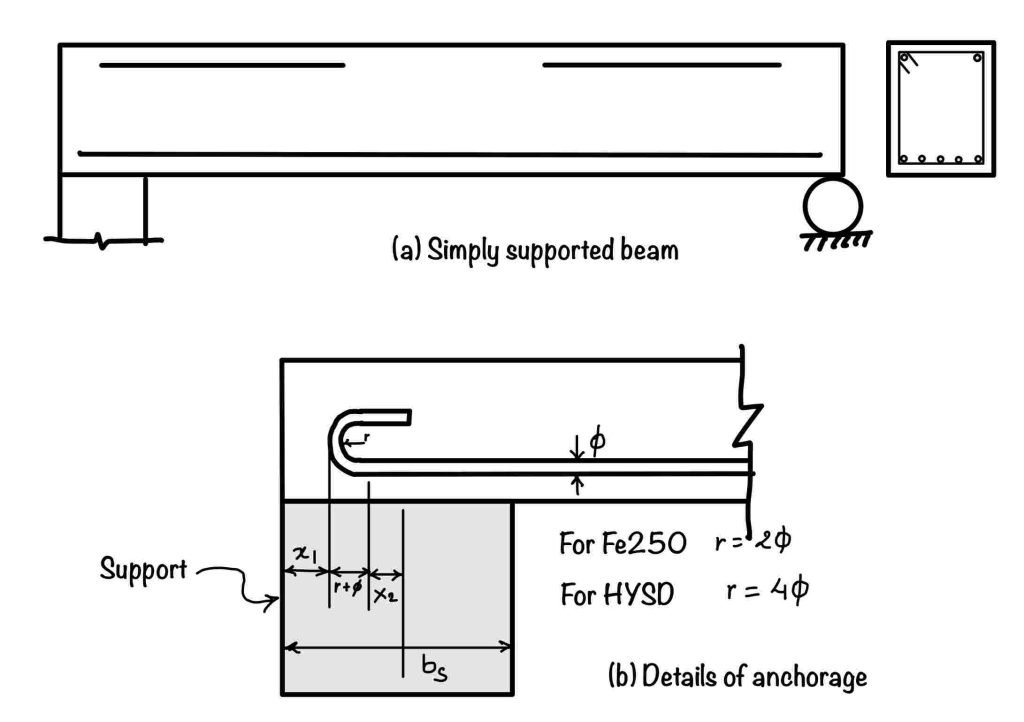

Lap lengths, hooks and anchorage (IS 456 highlights)

- Lap length in flexural tension: Use Ld or 30φ whichever is greater. This prevents undersized lap splices in thin members. Law Resource

- Lap length in compression: Equal to development length in compression.

- Staggering of laps: Splices are considered staggered when centre-to-centre distance ≥ 1.3× lap length. This reduces weakness zones. Law Resourcecivilera

- Bends and hooks: IS 2502 gives anchor values — for example, the anchorage value of a 180° U-hook = 16φ. Bends and hooks are treated as partial development length. Law Resource

Also Read Specific Gravity Test of Cement for Quality Concrete: Step-by-Step Guide

Factors that increase or reduce development length

Factors that reduce Ld (better bond):

- Higher concrete grade (stronger concrete gives higher τbd).

- Adequate concrete cover preventing splitting.

- Proper compaction and good concrete quality.

- Presence of transverse reinforcement near the bar (stirrups/links) that prevent splitting.

Factors that increase Ld (worse bond):

- Bars placed near free surfaces (bottom bars cast on ground).

- Bundled bars (adjacent bars reduce bond area; IS recommends percentage increases).

- Larger bar diameter (size effect).

- Poor concrete compaction, honeycombing, or loose cover.

- Corroded or rusty bars, or bars with poorly cleaned surfaces.

Practical detailing (stirrups, proper cover, bar spacing) helps reduce required Ld and improves structural performance. Law ResourceTheCivilStudies

Practical detailing tips for Indian sites

- Give at least the code Ld as free length beyond the critical section before cutting or lapping. Do not rely on hooks alone unless shown by code.

- Prefer straight anchorage where space allows; hooks and bends reduce Ld but need to meet IS 2502.

- Stagger lap splices—do not place many splices at the same section. Space them longitudinally and across layers.

- Avoid bundling bars where possible; if used, increase Ld per IS 456 (10–33% depending on count).

- Provide stirrups near lap zones to resist splitting; this can improve effective bond.

- Record Ld checks during reinforcement inspection and mark bars on site drawings to avoid confusion.

- For seismic regions, follow IS 13920 detailing: more conservative anchorage and lap practice is required. Law Resourcesefindia.org

Common site mistakes and how to avoid them

- Using the wrong σs — remember σs should reflect design stress (0.87fy for limit state).

- Forgetting to increase τbd for deformed bars — IS 456 requires a 60% increase.

- Placing laps in high-tension zones such as midspan tension (if unavoidable, provide extra reinforcement).

- Insufficient cover or poor compaction — both weaken bond.

- Not staggering laps — this creates planes of weakness.

Avoid these by checking details at the bar bending and placing stage, and by educating site staff on code basics.

Quick reference table: Ld (mm) for Fe415 — common diameters (M20, M25, M30)

| φ (mm) | M20 (≈47φ) mm | M25 (≈40φ) mm | M30 (≈42φ) mm |

|---|---|---|---|

| 8 | 376 | 320 | 336 |

| 10 | 470 | 400 | 420 |

| 12 | 564 | 480 | 504 |

| 16 | 752 | 640 | 672 |

| 20 | 940 | 800 | 840 |

| 25 | 1175 | 1000 | 1050 |

Use these only as a quick check. Exact Ld should be computed from the formula with correct τbd and σs for the project. Law ResourceThe Civil Engineering

When development length calculations are not enough

If you are unsure whether embedded reinforcement is properly anchored:

- Provide mechanical anchors or couplers for critical bars (especially for large-diameter bars or congested sections).

- Use headed bars or welded joints where permitted and qualified.

- Perform a check by using increased confinement (stirrups/links) in the anchorage zone—this increases capacity and can reduce needed Ld in practice.

- Consult a structural engineer for complex retrofits, heavy loads, or seismic detailing.

FAQs (Indian context)

Q1: What is the difference between development length and lap length?

A: Development length anchors a single bar to develop its stress. Lap length overlaps two bars so stress transfers from one to another. Lap length in flexural tension is Ld or 30φ, whichever is greater (IS 456).

Q2: Do we need to increase Ld for Fe500 compared to Fe415?

A: Yes. Since σs = 0.87fy is higher for Fe500, Ld increases proportionally unless τbd or other factors change. Use the formula to compute exact values.

Q3: Can hooks replace Ld?

A: Hooks and bends provide anchorage value as per IS 2502, but they must meet the code lengths (e.g., 16φ for a standard U-hook) and be used carefully.

Q4: How does concrete grade affect Ld?

A: Higher concrete grade increases τbd, reducing Ld. That’s why Ld in M30 is smaller than in M20 for the same bar.

Q5: Where do I find the official rules?

A: The authoritative source is IS 456:2000 (clauses 26.2 and related), and IS 2502 for bends and hooks. For seismic details use IS 13920. Always refer to the latest code editions. Law Resource

Conclusion

Development length is a key link between steel and concrete. It controls whether the reinforcement will work as intended. Use the IS 456 formula and τbd values as the starting point. Adjust for deformed bars, compression bars, bundled bars, and space constraints. Check lap lengths, use hooks and stirrups correctly, and always follow seismic detailing where relevant. Good detailing and adherence to code not only ensure safety but also save steel and effort.

If you manage construction or review drawings, keep a development-length checklist:

- Compute Ld by formula for each bar type and position.

- Verify lap lengths and stagger them.

- Ensure cover and compaction meet requirements.

- Provide stirrups near lap or anchorage zones.

- Consult IS 456 and IS 2502 when in doubt.

Follow these steps and your RCC detailing will be robust, efficient, and code-compliant.

Key references (for further reading)

- IS 456:2000 — Plain and Reinforced Concrete — Code of Practice (see clauses on development length, bond stress, lapping and anchorage). Law Resource

- IS 2502 — Code for bending and fixing of bars for concrete reinforcement (hooks and bends). Law Resource

- Practical guides and worked examples from Indian engineering sites that explain formula application and quick tables. The Civil EngineeringTheCivilStudies