In construction, BOQ and BOM are two different lists used for planning, estimating, and procurement. BOQ full form in construction is Bill of Quantities, and BOM stands for Bill of Materials. A Bill of Quantities (BOQ) is a document used in tendering that itemizes all work, materials, and labor (with quantities) needed for a project. By contrast, a Bill of Materials (BOM) lists only the raw materials, components, parts, and assemblies required to produce a structure or product.

BOQs are usually prepared by quantity surveyors or estimators for bidding (SRC-wikipedia). BOMs, on the other hand, are often prepared by design or production engineers to guide procurement and manufacturing. In simple terms, BOQ = materials + labor + services, while BOM = materials and components only. These documents help ensure accurate costing and smooth execution in construction projects.

What is BOQ (Bill of Quantities)?

A Bill of Quantities (BOQ) is a detailed list prepared after the design is complete. It breaks the work into measurable items (e.g. “Earthwork – 1.5m deep”, “RCC Slab 150mm thick”), and specifies the unit (such as cubic meter, square meter, or number), quantity, and unit rate for each item (SRC-procore). A BOQ enables all bidders to price the same quantities, so tender comparisons are fair. It often becomes part of the contract: payments are made based on the measured quantities from the BOQ.

- Purpose of BOQ: In civil engineering estimation, the BOQ helps calculate total project cost. It provides a common basis for bids so owners can compare proposals easily. It also defines the scope of work clearly, reducing misunderstandings about what is included. In many Indian government tenders (CPWD, PWD, DMRC, etc.), the BOQ forms part of the tender documents and is linked to interim payment schedules.

- Full Form: The BOQ full form in construction is Bill of Quantities. For example, Wikipedia defines a BOQ as a tendering document in which materials, parts, and labor (and their costs) are itemized.

| Item No | Description | Unit | Quantity | Unit Rate (₹) | Amount (₹) |

|---|---|---|---|---|---|

| 1 | Earthwork excavation (1.5m deep) | cum | 120 | 150 | 18,000 |

| 2 | Plain Cement Concrete 1:4:8 | cum | 20 | 600 | 12,000 |

| 3 | Brickwork with masonry 230mm thick | cum | 15 | 4,000 | 60,000 |

Also Read Basalt Rock Price & Uses in India

What is BOM (Bill of Materials)?

A Bill of Materials (BOM) is a list of all the materials, components, parts, and sub-assemblies needed to construct a building element or product. Unlike a BOQ, a BOM typically does not include labor or services. Instead, it focuses on the raw inputs and sometimes includes specifications or part numbers. BOMs are common in manufacturing and industrial contexts, but can also be used in construction for off-site fabrication or detailed assembly work.

- Purpose of BOM: A BOM serves as a recipe for ordering and assembling materials. It helps project teams plan material procurement, control inventory, and ensure quality. As Kreo Software notes, BOMs provide a clear outline of needed materials at each stage, enabling accurate cost estimation and efficient scheduling. For example, a contractor may use a BOM to list all rebar sizes and quantities for a structural frame, or all electrical components for an MEP system. Using the BOM, the team can source the correct quantities and avoid delays from missing parts.

- Full Form: BOM stands for Bill of Materials. In construction, the BOM is essentially an inventory of materials and parts required for the project. It is not usually part of a tender document, but it can be part of the contractor’s internal documentation or an EPC (Engineering Procurement Construction) bid for materials.

- Example Format: A simple BOM might have columns like

| Part No | Component | Specification | Quantity | Unit |

|---|---|---|---|---|

| 1 | Steel bar | Fe 500, 16mm dia | 100 | kg |

| 2 | Cement | OPC 43 grade | 50 | bags |

| 3 | PVC Conduit (elect.) | 20mm diameter | 100 | m |

- This BOM helps procurement ensure all items are ordered in the right amounts.

Purpose and Usage in Construction

The BOQ and BOM serve different roles in the construction workflow:

- BOQ Uses:

- Tendering and Cost Estimation: BOQ is critical for putting together a detailed bid. It allows clients or owners to compare contractor prices easily, since all bids use the same item list. It helps in creating a project budget and forming the contract price.

- Contract Management and Billing: Once work starts, the BOQ often becomes the basis for interim payments. Each billing cycle (RA bill), the contractor measures completed quantities against the BOQ and invoices accordingly. This “schedule of values” method makes progress claims transparent.

- Scope Definition: By listing every work item, a BOQ clearly defines what is included in the project. This minimizes disputes. Clients can see exactly what each bid price covers, reducing scope creep.

- BOM Uses:

- Procurement Planning: A BOM provides a consolidated list of materials to order, which streamlines purchasing. Teams can schedule deliveries and avoid shortages. As one source notes, BOMs simplify the procurement process by detailing everything needed.

- Production/Assembly: When elements of the project are prefabricated or assembled, the BOM guides the fabrication shop on what parts to prepare. It also helps in quality control by specifying exact materials and part numbers.

- Cost Estimation and Control: By listing raw materials and quantities, BOMs enable accurate material cost estimates. This is useful in EPC or turnkey projects where detailed materials pricing is needed.

In short, BOQs (with labor and service rates) are mainly used for civil engineering estimation, bidding, and construction contracts. BOMs are used for internal planning, procurement and production of construction components (SRC- netkreo).

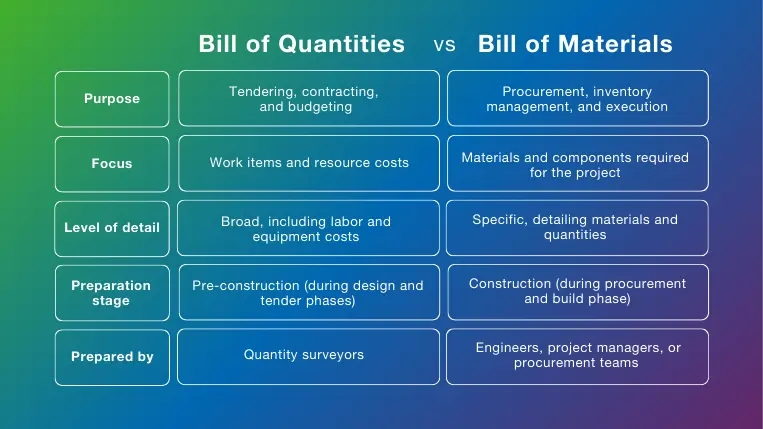

Differences: BOQ vs BOM

The table below highlights the key differences:

| Aspect | BOQ (Bill of Quantities) | BOM (Bill of Materials) |

|---|---|---|

| Full Form | Bill of Quantities | Bill of Materials |

| Items Included | Materials and labor/services | Only materials, components (no labor) |

| Purpose | Tender/bid pricing, budgeting, cost control | Material planning, procurement, and inventory management |

| Industry Context | Building and civil works (construction projects) | Manufacturing, fabrication, and EPC projects |

| Preparation Stage | After final design, before tendering (pre-construction) | During design or production phase (detailed planning) |

| Level of Detail | Aggregated work items (with quantities and rates) | Detailed breakdown of parts (often with specs/part numbers) |

| Format Example | Table of work items with unit, qty, rate, amount (often CPWD format) | List of part numbers, descriptions, and qty needed |

Sample Formats and Examples

BOQ Format (India): An Indian BOQ typically has columns for item number, description of work, unit, quantity, unit rate, and amount. For example:

| Item No | Description (Work) | Unit | Quantity | Unit Rate (₹) | Amount (₹) |

|---|---|---|---|---|---|

| 101 | Earthwork excavation (soft soil) | cum | 100 | 150 | 15,000 |

| 102 | Plain Cement Concrete 1:4:8 (for leveling) | cum | 20 | 700 | 14,000 |

| 103 | Brick Masonry (230mm thick) using FPS Bricks | cum | 15 | 5,500 | 82,500 |

This matches formats seen in CPWD/PWD tenders. Rates are usually taken from a schedule of rates or market analysis, and the total gives the estimate or tender sum.

BOM Format: A BOM might look like:

| Part No | Component | Specification | Quantity | Unit |

|---|---|---|---|---|

| 1 | Reinforcement Steel Bar | Fe500, 12mm diameter | 200 | kg |

| 2 | Cement (OPC 43 grade) | 50-kg bag | 100 | bag |

| 3 | Sand (Zone-II) | – | 5 | cum |

Each row lists a material/part with how much is needed. Unlike BOQ, there is no pricing or labor in a BOM.

Estimation, Procurement, and Billing

- Estimation: In civil projects, a quantity surveyor uses the BOQ to estimate total cost by multiplying quantities with rates. For example, if 100 cum of excavation is at ₹150, the cost is ₹15,000, as shown above. This is a standard part of civil engineering estimation and budgeting. A well-prepared BOQ helps in generating accurate project estimates.

- Procurement: The BOQ and BOM both feed into procurement. From the BOQ, contractors know the overall material needs and can plan bulk orders. The BOM provides a detailed shopping list of items to purchase. As one resource notes, a BOM “simplifies the procurement process by providing a comprehensive list of materials required,” helping with supplier negotiation and avoiding shortages. In practice, procurement teams use the BOM to place purchase orders and schedule deliveries for specific items like steel bars, cement, tiles, etc.

- Billing and Payments: The BOQ directly relates to billing in construction contracts. After work begins, contractors measure the completed quantities and multiply by the BOQ rates to claim payment. Procore explains that the BOQ “essentially becomes the schedule of values, making scope progress easy to calculate based on the amount of material on the job site and the work completed”. In other words, if 50 cum of excavation (from Item 101) is done in a month, the contractor bills ₹7,500 for that item. Over project milestones, BOQs help the owner track expenditures and cash flow.

In contrast, the BOM is not usually used directly for billing. It is a planning tool, though the costs derived from the BOM feed into overall project budgets.

Best Practices and Common Mistakes

- Use Standard Measurement (IS 1200): Follow the Indian Standard (IS 1200) methods for quantity measurement. This ensures consistency (e.g. how to measure brickwork, concrete) across projects. Standardization avoids misunderstandings over units and inclusions.

- Detailed, Clear Descriptions: Write clear descriptions for each BOQ item, including relevant specs (e.g. “Brick masonry with FPS bricks in cement mortar 1:6”). Similarly, in a BOM, include exact part names or codes to prevent confusion. Ambiguous items lead to disputes.

- Cross-Check Drawings: Ensure every item shown on the drawings is in the BOQ. A common error is missing an item. If a contractor finds a drawing detail not in the BOQ, they should query it immediately. Likewise, for a BOM, verify that all components of assemblies are listed. Example: If a beam drawing shows a certain grade of rebar, make sure that grade and length appear in the BOM.

- Avoid Omission and Duplication: A common mistake is forgetting small items (like waste allowance, temporary works, or connectors) or double-counting an item under two descriptions. Reviewing the BOQ by section and unit rates (e.g. from CPWD schedules) helps catch errors. Always reconcile the BOQ against the design.

- Update for Changes: If design changes, the BOQ and BOM must be updated. Failing to revise these lists can cause cost overruns and conflicts. Using BIM or software can help here: quantities can be regenerated if the model changes. According to Procore, more firms are using BIM to “easily create” and update BOQs.

- Check Calculations and Units: Simple arithmetic mistakes (wrong multiplication) or wrong unit interpretation (e.g. confusion between cum and sqm) are frequent problems. Use software tools or spreadsheets to reduce math errors.

Use in Software and Technology

Modern projects often leverage software for BOQ and BOM:

- Excel and Templates: Many teams use Excel/Sheets with formulas for BOQ and BOM. Custom templates (sometimes based on CPWD formats) help standardize data entry. Excel’s calculation abilities also reduce arithmetic errors.

- CAD and BIM Tools: CAD software (AutoCAD) can be used for takeoffs: measuring areas/lengths from drawings. Autodesk Takeoff or Revit (BIM) can generate quantity lists directly from the model. As noted, architects and engineers increasingly use BIM to prepare BOQs. BIM can also produce a BOM of materials (e.g. a list of each type of panel in a prefab design).

- ERP and Construction Software: Enterprise solutions like Tally, SAP, Oracle, or specialized ERP (e.g. Realx ERP) include modules for estimation and procurement. They can handle BOQ rate analysis, generate BOM for procurement, and even link with billing. For example, construction ERP software often supports BOQ upload, cost tracking, and material stock management. (While sources are marketing in nature, many Indian EPC software suites list BOQ and BOM modules in their features.)

- Quantity Surveying Software: There are dedicated BOQ/BOM tools (like CostX, PriMus) that integrate takeoff and rate database. These automatically compile BOQs from drawings and manage databases of material costs, streamlining estimation.

- Others: Even accounting systems (Tally) may track material inventory from BOM, and invoicing can be tied to BOQ line items.

Indian Standards and Updates

In India, BOQs follow guidelines in government manuals and standards:

- CPWD Works Manual: The CPWD (Central Public Works Department) manual (2014, 2019, 2022 editions) outlines the format and preparation of BOQs. Many central and state agencies adopt these formats. It sets rules for contingencies, abstract of costs, and detailed BOQ sections.

- Indian Standard IS 1200: This is the main code for method of measurement of building and civil works. Following IS 1200 ensures that quantities are calculated uniformly. For example, “Brick masonry” is measured by area (sqm) per IS 1200 clauses.

- Schedule of Rates (SSR/DSR): While not a measurement code, the Delhi Schedule of Rates and similar state schedules provide standard rates that are often used in BOQ rate-building in government projects.

- E-procurement Portals: Modern Indian tenders (CPP portal, GeM) require BOQ upload in prescribed digital format (often Excel). These portals enforce the format (headers like SR No., Description, UoM, Quantity).

- IS Codes for Specific Works: Additional IS codes (e.g. IS 7272 for earthwork, IS 875 for loads) may indirectly affect BOQ content.

No single new “BOQ code” was issued recently, but construction departments periodically update manuals. For example, the CPWD manual 2022 is the latest reference. Following these ensures compliance in government tenders.

BOQ vs BOM: Quick Comparison Table

| Comparison | BOQ (Bill of Quantities) | BOM (Bill of Materials) |

|---|---|---|

| Includes | Materials + labor + equipment + services | Only materials/components (no labor) |

| Usage | Tender bidding, contract valuation, interim billing | Material ordering, fabrication, and assembly planning |

| Industry/Application | Civil engineering and infrastructure projects | Manufacturing, EPC projects, electrical/MEP installation |

| Preparation Time | Pre-tender (after design is finalized) | Pre-construction or during detailed design |

| Detail Level | Broad work items with units and rates | Detailed part/item breakdown (often with specs/codes) |

| Format (example) | Item No, Description, Unit, Qty, Rate, Amount | Part No, Component, Spec, Qty, Unit |

FAQs

Q1: What does BOQ stand for in construction?

A1: BOQ stands for Bill of Quantities, a detailed list of the work items (materials, labor, etc.) and their quantities. It is used for tendering and estimating.

Q2: What does BOM stand for?

A2: BOM stands for Bill of Materials, which is a list of all materials and parts required to build a component or product. Unlike a BOQ, a BOM usually excludes labor or service items.

Q3: How is BOQ used in civil engineering estimation?

A3: In civil engineering estimation, the BOQ provides quantities of each work item. The estimator applies unit rates (from schedules or market rates) to these quantities to compute the project cost. This makes estimating systematic and comparable across bidders.

Q4: Is BOQ format standardized in India?

A4: Yes. Government tenders (CPWD, PWD, Railways, etc.) follow a standard BOQ format as per CPWD manuals and IS guidelines. Typically, columns include item number, description, unit, quantity, rate (in figures and words), and total amount.

Q5: Does BOQ include labor costs?

A5: Yes. A BOQ includes both materials and labor (and sometimes equipment or other costs) itemized separately. This is a key difference from a BOM.

Q6: Who prepares the BOQ?

A6: A BOQ is usually prepared by a quantity surveyor or a building estimator based on the completed design drawings and specifications. They must follow the standard measurement rules (IS 1200) and departmental manuals.

Q7: Which is better for software, Excel or AutoCAD?

A7: Many teams use Excel/Sheets for BOQ/BOM because of its flexibility and calculation power. However, AutoCAD/Revit (BIM) can generate quantities directly from models. For example, BIM software can produce updated BOQs as designs change. ERP software can manage both BOQ (for costing) and BOM (for procurement) in a unified way.

Q8: Is BOM mandatory in government tenders?

A8: Not usually. Government tenders require a BOQ for bidding. BOMs are generally internal to contractors or used in manufacturing contracts. Some EPC contracts may involve a BOM, but it’s not a standard tender requirement like a BOQ.

Q9: What mistakes should be avoided in BOQ and BOM?

A9: Common mistakes include missing items, incorrect units, or arithmetic errors. Best practices are to double-check quantities against drawings and follow IS 1200 measurement rules. For BOQs, any discrepancy between the drawings and BOQ should be queried. In BOMs, ensure all components and their specifications are listed to prevent procurement issues.

Q10: Where can I find BOQ templates for civil engineering?

A10: Many free BOQ templates are available online (e.g., Excel files based on CPWD formats). Professional construction software and BIM tools often have built-in templates. Always ensure any template follows the Indian standard format (item number, description, unit, quantity, rate, etc.).

Conclusion

Both BOQs and BOMs are essential for project planning, but they serve different needs. The BOQ is a tendering document for construction projects that includes materials, labor, and costs. It helps with bidding, budgeting, and contract payments. The BOM lists just the materials and components needed, aiding procurement and manufacturing planning. In India, construction projects (especially government works) rely heavily on BOQs following CPWD and IS standards. Best practice is to prepare accurate and detailed BOQs and BOMs, use software tools to manage them, and regularly update them as designs evolve. This ensures smooth execution, cost control, and fair payments in construction projects.