Civil engineering is the branch of engineering that deals with designing, constructing, and maintaining the physical infrastructure around us – roads, bridges, canals, dams and buildings. Civil engineers often work on creative projects that help communities, which makes this field both challenging and rewarding. If you are preparing for a civil engineering job interview, you should be ready to answer both general/HR questions and technical questions. General questions might cover your background, goals and motivation, while technical questions will test your engineering knowledge. Below, we discuss common civil engineering interview topics and sample answers. This guide is written in simple English for clarity and includes examples, tables, and answers to frequently asked questions.

General and HR Questions

Interviewers often begin with general questions to get to know you and your motivations. For example, they may ask “Tell me about yourself.” In this answer, describe your education, any internships or projects, and why you chose civil engineering. Questions about motivation are common: “Why do you want to become a civil engineer?” Use this to show your passion. For instance, one candidate said they loved building things and solving puzzles since high school, which drove them to pick civil engineering.

Another set of general questions tests your planning and research skills. Expect “Why do you want to work for our company?” Interviewers want to see if you know their projects or mission. As one sample response suggests, you should mention specific qualities of the firm, such as its reputation or standards, to show you have done your homework.

Other typical HR-style questions include: “What are your strengths and weaknesses?”, “What are your short-term and long-term goals?”, and “What draws you to civil engineering?”. Answer honestly and focus on skills or goals related to engineering. For example, you might say your strength is problem-solving, and your goal is to work on large infrastructure projects. You might also be asked “Tell me about a challenge you overcame.” These behavioral questions (e.g. a time you solved a problem in a project) let you demonstrate teamwork or leadership. Finally, don’t forget common closing questions like “Do you have any questions for us?” — this is your chance to ask about the company’s civil projects or team.

Core Technical Questions

After general questions, interviewers will ask technical questions to assess your civil engineering knowledge. These can cover materials science, structural design, geotechnical concepts, construction practices, and more. Below are key topics and sample questions you should prepare for.

Engineering Basics: Definitions and Concepts

- What is civil engineering? Civil engineering involves the design, construction, and maintenance of infrastructure and built environments. It includes projects like roads, bridges, canals, dams, and buildings. In an interview, mention that civil engineers ensure structures are safe, durable, and functional.

- Branches of civil engineering: It’s useful to know major subfields. Common branches include Structural Engineering (design of buildings, bridges), Geotechnical Engineering (soil and foundations), Transportation Engineering (roads, highways, railways), Water Resources Engineering (dams, irrigation), Environmental Engineering (water supply, pollution control), Construction Management, Coastal Engineering, and Surveying. You don’t need to cite every branch, but mentioning a few shows breadth.

- Cement vs. Concrete: Many interviews start with basic definitions. For example, “What is the difference between cement and concrete?” A simple answer is: Cement is the grey powder (a binder made of calcined limestone and clay), while concrete is a composite of cement, sand, gravel, and water that hardens over time. Cement is just one ingredient; concrete is the final building material.

- Reinforced Cement Concrete (RCC): If asked “What is RCC?”, answer that RCC (Reinforced Cement Concrete) is concrete embedded with steel bars. This combination leverages concrete’s strength in compression and steel’s strength in tension. For example, one example answer explained RCC as concrete combined with ductile steel to enhance tensile strength (SRC- Indeed).

- Purpose of reinforcement: You may be asked why we put steel in concrete. Reinforcement (steel bars) is used to increase tensile strength and control cracks. In plain words, concrete is strong when squeezed (in compression) but weak when pulled (in tension). Steel bars carry those tensile loads. For example, reinforcement helps concrete resist bending, shrinkage cracks, and shear forces.

- Types of loads: Know the types of loads on structures. A common answer is: Dead loads (the weight of the structure itself), Live loads (people, furniture, vehicles), Wind loads, and Seismic loads. For instance:

- Dead Load – constant weight of beams, walls, floors (it does not change).

- Live Load – moving or variable loads like occupants, furniture, vehicles.

- Wind Load – force from wind pressure on structures.

- Seismic Load – earthquake forces on structures.

These four cover the basics. You should be able to define each briefly.

Concrete and Materials

Concrete is the most common material in civil projects, so expect many questions about it.

- Concrete mix grades (M10, M20, etc.): In India, concrete is often specified by grade (M20, M25, etc.). An interviewer might ask “What does M25 mean?” or “What is the compressive strength of M20?”. You can answer that M25 means a target strength of 25 MPa at 28 days, with a typical nominal mix ratio of 1:1:2 (cement:sand:aggregate). Similarly, M20 concrete has 20 MPa strength at 28 days. A useful way to remember nominal mix proportions for common grades is by table. For example, one source lists the following nominal mixes: Concrete GradeMix Ratio (Cement : Sand : Aggregate)M101 : 3 : 6M151 : 2 : 4M201 : 1.5 : 3M251 : 1 : 2M301 : 1 : 1 (This table shows nominal mix proportions for concrete grades, as commonly cited in interviews.) You don’t have to memorize all values, but know how to explain what an M-designation means (e.g. M25 = 25 MPa).

- Water-cement (W/C) ratio: “What is the water-cement ratio?” is a common question. The W/C ratio is simply the weight of water divided by weight of cement in a concrete mix. It strongly affects strength and durability. Typically, good-quality concrete uses a W/C ratio of about 0.40–0.50 (SRC-civilpracticalknowledge). A lower ratio means stronger concrete (but less workable), and a higher ratio means weaker concrete (but more fluid). Mention that as long as you know the definition and a typical range (around 0.45), you are fine.

- Slump test: Interviews often ask about the slump test, which checks concrete workability. The slump test involves filling a cone with fresh concrete, lifting the cone, and measuring how much the mix settles (the “slump” height). A related question could be “What does slump tell us?” It measures how easily concrete flows. According to standard categories: High slump (>150 mm) means very workable (used for pumping), Medium slump (75–150 mm) is normal workability, and Low slump (<75 mm) means stiff concrete (used for road-base concrete). In simpler terms, high slump means wet mix, low slump means dry stiff mix. We summarize slump categories here: Slump Range (mm)WorkabilityTypical Use> 150 (High slump)Very workableFor pumped concrete75–150 (Medium)NormalGeneral construction concrete< 75 (Low slump)Low workabilityRoad and heavy-duty concrete Table: Slump test categories and their typical implications (from concrete quality standards).

- Types of slump (observations): Another slump question might be “What is true slump, shear slump, collapse slump?” These describe how the concrete behaves when the cone is lifted. A true slump means the concrete subsides uniformly (retains shape). A shear slump means one side falls a bit (lack of cohesion). A collapse slump means the mix is very wet and collapses entirely. You might not need to recall all these for a general interview, but it shows attention to detail.

- Bleeding: “What is bleeding in concrete?” Bleeding is when excess water rises to the surface of freshly placed concrete. As it hydrates, water can separate and form puddles on top. This weakens the concrete surface. In short, bleeding is segregation of water in a wet mix and should be minimized. A brief answer: “Bleeding is when water separates out of the mix and comes to the top, which can weaken the top layer of concrete”( SRC-Indeed).

- Curing: Questions like “What is curing and why is it done?” Curing means keeping concrete moist for a period after placement so that it can properly harden (gain strength). Explain that proper curing (keeping water in the concrete) ensures higher strength and durability. In India, the standard code IS 456:2000 requires at least 7 days of curing for ordinary Portland cement and more (10–14 days) for blended or harsh conditions. For example, you could say: “As per Indian standard IS 456, concrete should be kept moist for about 7 days (10 days if using pozzolanic cement) for proper strength.” Concreting steps: If asked about the steps in concreting, mention: batching ingredients, mixing them, transporting/place concrete in formwork, compacting it (e.g. with a vibrator), and then curing. One detailed source lists 6 steps of curing like shading, keeping water-soaked blankets, etc.. You can just give the main steps. For curing, say you keep the concrete wet (using water spray, wet jute bags or plastic sheets) for about a week after pouring.

- Concrete tests: Interviewers often ask “What tests do you use for concrete?” The main tests are compressive strength test (breaking a hardened cube or cylinder) and the slump test for workability. You can say: “Typically, we test cured concrete in compression to verify its strength, and we use the slump test on fresh concrete to check workability.”

Structural Engineering Concepts

Structural engineering questions focus on building elements and behavior under loads.

- Beams and types: You may get asked “What is a beam?” – a beam is a horizontal structural element that carries vertical loads and resists bending. Key types: simply supported, cantilever, continuous, overhanging, etc. For example, a cantilever beam is fixed at one end and free at the other (like a balcony). A continuous beam extends over several supports.

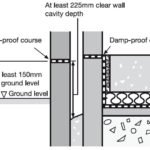

- Columns and foundations: Know the difference between shallow and deep foundations. A shallow foundation is usually less than about 3 m deep (like spread footings, rafts) and is used when good soil is near the surface (SRC-geeksforgeeks). A deep foundation (piles, caissons) goes deep (>3 m) to reach stronger soil or rock when topsoil is weak. For example: “We use shallow (spread) footings for lighter loads on strong soil, and pile foundations for heavy loads or poor soil.” The main types of foundations in practice are shown here.

- Shallow foundation: Spread footing, combined footing, raft footing.Deep foundation: Pile foundation, well (drilled) foundation.

- Soil testing: If asked “Why is soil testing important?”, mention that understanding the soil is crucial for safe design. Soil tests determine how much load the soil can carry (bearing capacity), how much settlement to expect, and what type of foundation to use. It also can reveal problematic soils (like expansive clay) and help design improvements (like compaction or drainage).

- Bearing capacity vs settlement: These terms are often confused. Explain that bearing capacity is the maximum pressure soil can take without shear failure, whereas settlement is how much the foundation will sink under load. Bearing capacity is about strength; settlement is about compressibility.

- Retaining walls: If you mention retaining walls: “A retaining wall holds back soil. The main types include gravity walls (rely on weight), cantilever walls, sheet-pile walls, anchored walls, and reinforced earth walls.”

- Other structural elements: You might be asked about slabs (one-way vs two-way), columns, or special beams (flange beams). For example, one-way slab carries load in one direction (when length is >2× breadth), and two-way slab bends in both directions. A flange beam might come up: it’s a beam with an extended top/bottom flange (like an I-beam); if asked, say stirrups are typically spaced more closely near the flange.

- Prestressed concrete: Advanced interviews may ask about prestressing. You can say prestressing is a method of applying initial tension to steel in concrete (either before or after casting) to improve its performance in service. Pre-tensioning means tensioning the steel before the concrete sets, while post-tensioning means tensioning after the concrete has hardened. These methods give concrete greater load capacity and less cracking.

Construction Management and Safety

Interviewers also evaluate how you handle project work:

- Project management: You may be asked about managing multiple projects or teams. For example, “How would you prioritize your work with multiple projects?” or “Do you have experience as a project manager?” Answer by describing time-management, planning tools (like Gantt charts), and communication skills. If asked about scheduling, you might mention tools like MS Project or Primavera and methods such as critical path analysis.

- Safety: Safety is a top priority on construction sites. A typical question is “How do you maintain a safe work environment?” A good answer: talk about wearing proper gear (PPE), following regulations, conducting safety briefings, and stopping work if unsafe conditions are found. For example, one sample answer was: “Safety on a construction site is my absolute top priority. I always make sure everyone has proper protective equipment before work starts and enforce site rules. If I see an unsafe condition, I stop the work immediately until it is fixed.”. You can cite OSHA or BIS safety codes if you know them, or simply emphasize communication and compliance.

- Quality control: Civil projects require quality checks. You might be asked, “How do you ensure concrete quality on site?” Mention testing materials (like slump test, cube tests), checking mix ratios, supervision of formwork and compaction, and curing. Similarly, for work supervision: “How do you interact with clients or contractors?” Show that you will communicate clearly, report progress, and resolve conflicts professionally.

- Tools and charts: Sometimes questions cover tools like a Gantt chart (for scheduling projects). If asked “What is a Gantt chart?”, answer that it is a bar chart showing the timeline of project tasks (start and end dates) and is used for planning and monitoring construction schedules.

Indian Context Notes

Since you may be interviewed in India, it helps to mention relevant standards and examples:

- Indian Standards (IS codes): Civil engineers in India follow BIS codes. For instance, IS 456:2000 covers concrete design and construction. You might say “As per IS 456, concrete grade strengths are defined after 28 days of curing” or “Per IS code, minimum curing periods are 7–14 days.” Also, India follows IS 1077 for brick sizes: a standard brick is 190×90×90 mm (without mortar).

- Units and materials: India often uses metric units (mm, MPa, kN/m³). If asked about brick size, answer: “Standard brick size in India is 190×90×90 mm (200×100×100 with mortar).” If asked about concrete weight: plain concrete is about 24 kN/m³, reinforced about 25 kN/m³.

- Grades and materials: Mention common materials in India: OPC (Ordinary Portland Cement) grades (33, 43, 53), PPC (Pozzolana Cement), and so on. Also, know common construction practice terms like QCB (Quality Control Bonds), PCC (plain cement concrete) vs RCC, etc. For example, you could be asked “What is PCC?” – answer that PCC is plain (unreinforced) concrete used for base levelling, whereas RCC has steel bars.

- Projects and environment: You might be asked how you would design for Indian conditions (monsoon rains, earthquakes). For example, “How do you design structures for heavy rainfall?” or “How do you account for seismic loads?” Show awareness of local climate: mention drainage, water-proofing, or earthquake-resistant design if relevant.

Sample Technical Q&A

Here are a few specific questions and how you might answer them:

Q: Why do we need reinforcement in concrete?

A: Concrete is strong in compression but weak in tension. Reinforcement (steel bars) gives concrete tensile strength and controls cracking. It also lets us use less concrete with more slender sections. For example: “Reinforcement increases concrete’s tensile strength and improves ductility, so the structure can safely carry bending loads.”

Q: Explain the slump test and its results.

A: The slump test measures concrete workability. You fill a slump cone with fresh concrete, lift the cone, and measure the vertical settlement. A high slump (>150 mm) means very workable concrete (useful for pumping), medium slump means normal workability, and low slump (<75 mm) indicates stiff mix (used for pavements). You can mention that this helps ensure consistency across batches.

Q: What is curing and why is it important?

A: Curing means keeping concrete moist after placing. Proper curing ensures the cement hydration reaction can continue, giving maximum strength and durability. In India, codes say to cure for at least 7–14 days depending on cement type. You can describe practical methods: covering with wet jute or plastic and keeping it damp.

Q: Name types of foundations and when to use them.

A: The two main categories are shallow and deep foundations. Shallow foundations (like spread footings, combined footings, raft) are used when good soil is close to the surface. Deep foundations (piles, drilled shafts) are used when you need to transfer loads far down to stronger soil/rock. For example: “For a normal house on firm soil, a shallow spread footing is typical. For a tall building or in weak soil, we might use driven piles to reach a sturdy layer”.

Q: What is a retaining wall and its types?

A: A retaining wall holds back soil at different elevations. Types include gravity walls (massive concrete/stone relying on weight), cantilever walls (reinforced concrete walls with a thin stem), sheet-pile walls (steel sheets driven into soil), anchored walls (with cables back into the ground), and reinforced earth walls. You can list a few types as needed.

Q: How do you ensure quality on site?

A: Emphasize checking specifications and doing tests. For example: verify mix proportions, supervise concrete pouring, test sample cylinders for strength, do slump tests, check reinforcement placement, and follow all drawings. Mention safety gear, inspections, and following codes (like IS codes).

Q: How do you solve problems or make decisions on site?

A: Talk about practical approach: use engineering judgement, consult codes, communicate with team, and document solutions. For example: “If a design conflict arises, I would first verify calculations, consult the drawings and code, then discuss with the senior engineer or client to agree on a safe solution.”

Q: What civil software are you familiar with?

A: Many interviews ask this. Mention any CAD (AutoCAD, Revit), design software (STAAD Pro, ETABS, SAFE), project tools (MS Project), or even Excel. Relate them to tasks: e.g., “I use AutoCAD for drafting structural details, and STAAD Pro for structural analysis. I’ve used Excel for quantity estimation as well.”

Tips for Indian Civil Engineering Interviews

- Review fundamentals: Make sure you remember key formulas and definitions (e.g. strength formulas, unit conversions, code values like concrete unit weight ~25 kN/m³). Practice explaining them in simple language.

- Know IS codes: If interviewing in India, reference relevant codes (e.g. IS 456 for concrete, IS 3370 for water tanks, IS 875 for loads). Even a general mention shows professionalism.

- Prepare project examples: Be ready to talk about any college project, internship work, or construction project you have done. Describe your role and what you learned.

- Research the company: As noted earlier, learn about the company’s projects or values. If it’s an infrastructure firm, mention interest in large projects. If it’s a consultancy, mention liking design work. This will help answer “Why work here?” effectively(SRC-Indeed).

- Practice communication: Speak clearly and confidently. Use short sentences. If you don’t know an answer, it’s better to be honest and say you will learn, rather than guess badly.

- Ask your own questions: At the end, have a few questions ready, such as “What software does your team use?” or “What are the current projects I might work on?” This shows enthusiasm.

FAQs

1. How do I prepare for common civil engineering interview questions?

Review the basics (materials, structures, loads, soil mechanics). Practise explaining them out loud. Use resources like textbooks or career sites (e.g., GeeksforGeeks, Indeed) to get example questions. Also, rehearse general interview questions (self-introduction, goals, strengths).

2. What topics should I study for a civil engineering interview?

Focus on core subjects: Concrete technology, Steel design, Soil mechanics, Surveying basics, Hydraulics and water resources, Construction management. Also revisit Indian standards (IS codes) and any specialized area of the job (e.g., highway or water if applicable).

3. How do I answer “Tell me about yourself” as a civil engineer?

Briefly summarize your education, any relevant internship or project experience, and why you chose civil engineering. For example: “I completed my B.Tech in Civil Engineering at XYZ University, where I worked on a bridge design project. I enjoy solving structural problems, which motivated me to pursue this field.”

4. What is the difference between technical and HR questions in these interviews?

Technical questions check your engineering knowledge (e.g. “What is the purpose of reinforcement in concrete?”). HR/general questions are about you personally (e.g. “What are your strengths?” or “Why do you want this job?”). You should prepare for both types. Always be honest and connect your answers to the role.

5. How important are practical experiences and projects?

Very important. Interviewers love hearing about real examples. Discuss any college lab work, projects, or internships where you applied civil engineering concepts. Explain your contribution and what you learned, as this shows practical readiness.

6. How do I ask questions to the interviewer?

Prepare at least one or two questions. They can be about the role (“What software does your team use?”) or about projects (“Can you tell me about a recent project the team completed?”). Good questions show your genuine interest.

Conclusion

In summary, a civil engineering interview will test both your technical knowledge and your communication skills. Study fundamentals like concrete mixes, structural loads, foundation types, and standard tests. Practice explaining concepts simply. Also prepare for HR questions about your goals and teamwork. Mention relevant Indian standards (like IS codes) to show preparedness for local practice. By reviewing common questions and practicing answers, you can enter the interview confident that you are well-prepared. Good luck!